By Ctein

I've just finished printing up a bunch of "art quality" 11 x 14 prints for my Contributors, and I'm so frustrated I feel like tearing my hair out. (Yes, I have plenty to spare. What's your point?) The amount of time and money I waste because of shoddy inkjet paper manufacturing practices is appalling.

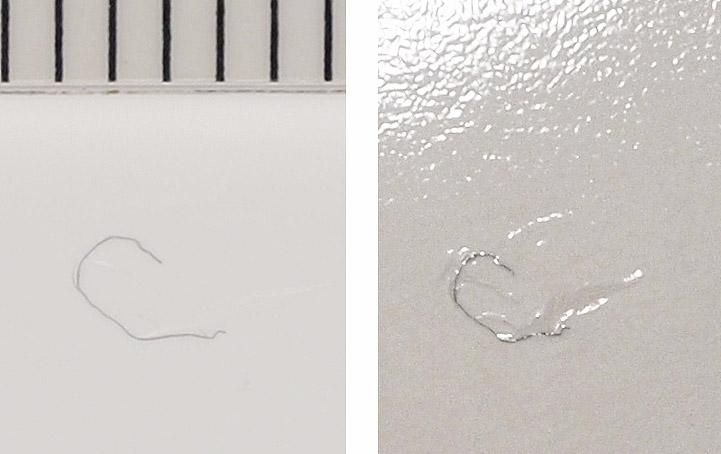

This is not about aesthetic qualities like tone and color rendition or D-max. I'm talking about genuine manufacturing defects: fibers embedded in the emulsion (figure 1), bubbles and pinholes, inclusions that penetrate the surface (figure 2), and highly visible scuff and scratch marks straight from the factory.

Figure 1. This kind of manufacturing defect is very easy to find (ruler

markings in mm). Unfortunately, it's the least common. The flaw would

stand out in a light or dark area, because there is damage to the

surface relief, as you can see in the grazing-light photograph on the

right.

Figure 1. This kind of manufacturing defect is very easy to find (ruler

markings in mm). Unfortunately, it's the least common. The flaw would

stand out in a light or dark area, because there is damage to the

surface relief, as you can see in the grazing-light photograph on the

right.

Figure 2. This is by far the most common kind of manufacturing defect. It is

almost invisible (it's between the arrowhead and the ruler) but if

printed upon will produce an obvious flaw. It takes a lot of time going

over blank paper to catch these defects and I'm only partly successful.

This isn't a big problem with "RC" papers. It's when you move into the world of fiber papers that you start to endure a world of pain. I've yet to try a fiber-based paper where I don't get a couple of bad sheets per box. The standards of some of the paper manufacturers are astoundingly low. The Harman FB Al glossy paper, which I love for its appearance, is atrocious; I typically reject a quarter of the sheets in a box of 11 x 17" sheets. The larger the size of the paper, the more rejects. For 17 x 25 sheets, far fewer than half are good.

Traditional light-sensitive photographic paper manufacturers dealt with exactly the same issues. It takes more attention to quality control and cleanliness, and more critical standards for your raw materials to make a good fiber-based paper than an RC paper. Coating the base with plastic eliminates a multitude of manufacturing problems. Wonder of wonders, they figured out how to do that; it is not, in fact, rocket science. We expected high quality paper, and we were entitled to do so. It's no fun going to the trouble of making a darkroom print, getting the finished print on the viewing table, and discovering some gross physical flaw that makes it unusable. When we did, we screamed bloody murder, and most of the time paper manufacturers responded appropriately.

It's not about "getting what you pay for" (or any other supplier-centric apology). Fiber inkjet papers are not cheap; in constant dollars, they are frequently more expensive than silver gelatin B&W darkroom papers were. We're paying premium prices; we're getting substandard goods.

Although I wouldn't be any happier if the stuff were dirt cheap. Lousy paper costs me, even if the paper were free. If I make a print on a defective piece of paper, I've wasted a couple of dollars of ink as well as the time it took the computer and printer to create the work. The printing costs and time are avoidable...if I successfully weed out the defective sheets before I print. That time and trouble is considerable. A minority of paper defects are so horrendous that they'll just jump out at you at a casual glance (figure 1). Most of them, though, are small white-on-white defects that are nearly invisible in an unprinted sheet of paper (figure 2) although, once you lay a bunch of dark ink on them, they will catch the light and they will stand out like blemishes on an adolescent's forehead. I have to check unprinted sheets closely at just the right angle, under the right mix of diffuse and specular light, to catch those flaws.

Some photographs are fairly forgiving of paper flaws; they are light enough and busy enough that I can get away with using slightly defective sheets. A photo like the Weathered Sulfur Vents (figure 3) will survive slightly-less-than-perfect sheets; I know the viewer is never going to see a very slight flaw. Unfortunately, that's not many of my photographs. A photograph like Floodlit Colombia (figure 4) is utter hell. Even after weeding out 30% of the sheets, there's still a 25%–30% chance that I've missed some defect that will be glaringly obvious after I've printed out the photograph.

Figure 3. A photograph like this can tolerate one or two very small surface

defects, because it's mostly light in color and very busy.

Figure 3. A photograph like this can tolerate one or two very small surface

defects, because it's mostly light in color and very busy.

Figure 4. A photograph like this needs a pristine surface to be printed on,

because any emulsion defects catch the light and are glaringly obvious.

Figure 4. A photograph like this needs a pristine surface to be printed on,

because any emulsion defects catch the light and are glaringly obvious.

There is no excuse for this. Simply none. The paper manufacturers are getting away with using incompetent manufacturing techniques and expertise and selling us garbage. And, unfortunately, the vast majority of nouveau digital printers have not a clue that the paper manufacturers can do much, much better if their feet were held to the fire, and they do not understand that they should expect better.

Unlike so many of the technical problems I face in fine printing, shoddy paper is one I have no fix for. Damn and double-damn.

All photographs copyright 2010 by CteinCtein's regular weekly column appears every Thursday morning.

Featured Comment by Miserere: "Your struggle felt familiar, and I just realised why: This problem is reminiscent of when my sister used to play the clarinet. For those that don't know, you need to place a wooden reed on the mouthpiece which, when vibrated as you blow, produces the instrument's sound. All woodwind instruments have them as far as I know (and saxophones too).

"Well, they sell these reeds in packs, and they're not cheap. My sister would buy packs of ten, open them, then spend an hour testing the reeds individually. I don't remember exact numbers, but it went something like this: 3–4 reeds would be unusable and get thrown out, 5–6 would be fine to practice with, 1 would be superlative and she would mark it and save it for performances and exams. If you bought the more expensive reeds, you simply increased your odds of getting more usable ones, but we did the math and it was more cost-effective to buy the cheap packs and throw 3–4 away than buy the more expensive ones and throw 2–3 away. I remember saying to her once 'but surely there must be some brand that sells boxes with 10 good reeds, or maybe a box of 3 guaranteed excellent reeds!' She insisted there wasn't."

Mike adds: And try buying vinyl records. Ironically I have 50-year-old records that have numerous flaws and defects that I find perfectly satisfying to listen to, but it's really annoying to spend $50 on a current two-disk, 45 RPM deluxe superdisk and find it comes out of the shrinkwrap with multiple flaws baked in. Vinyl is only about 10% of my listening, and I just do it for fun—I don't really need to mess with it at all—but it's still amazing how elusive good QC can be. I recently bought three copies of Dexter Gordon's "One Flight Up" on Cisco and just had to give up.

In general, Ctein's point is just further evidence of one of my pet theories: that digital inkjet printing is actually the opposite of "all you have to do is push a button." Q&D lowbrow digital printing is easy as pie, but really top-level digital printing might actually be harder than darkroom printing of a similar level, unless you do a lot of it and do all the work to keep everything tuned and humming.

Featured Comment by John Custodio: "That's why I never print on roll paper. I examine each sheet before I print on it, which I can't do if it's in a roll. I've had lots of problems with Museo Silver Rag with specks and junk in the coating, also similar problems with Hahnemuehle Photo Rag Baryta. Recent batches of these two papers are fine, however. Seems like they've solved the problems, at least for now.

"In my opinion, the weakest step and what causes me the most lost time in the entire digital process (shooting, Photoshop, printing) is printing. And the weakest link in the printing process (color management, ink, paper) is the paper!"

Featured Comment by Michael W: "Funny story about fibers in photographic paper. Back when I was going to college in the late '80s my father worked for a paper mill, and they had a summer work program for college students if their parents worked at the mill. The last summer I was there I was assigned to one of the slow but high-quality machines. We had a run of dense bleached coated stock that was as I was told for a large American photo company. The QC on this run was much much higher, so much so that the QC department set up a station at the end of the line. One day at the start of the shift I was asked by one of the lowest hands on that machine to help him drop some powdered additives for the coating into a hot mixing vat about halfway down the line. I was helping him pour the powder out of 50 lbs. brown bags. One of them got a away, and a piece of the bag about 8 x 12 inches wound up in the vat. Talk about some upset people. the mill manager came down, the QC guys came down, everyone came down and waited. Finally about ten minutes later, small brown fibers started showing up in the 12x12 samples pulled off by QC...well, the run as it came off the rollers went right back into the process at the start of the line to be rebleached and remilled...long story short, when I came back the next day, 24 hours later, QC was still rejecting the run. It wound up taking nearly four shifts to get all of the brown fibers from that 8x12 piece of bag out of the system. Needless to say I was not asked to help with pouring again...."

Featured Comment by Matthew C.: "I'm ready for the end of paper myself....

"I have 100+ fine art nature prints from some of the top landscape photographers sitting at home piled in a closet. And they are beautiful, and I love them and bring them out every month or two just to savor the beautiful images. But I'd enjoy them even more if I could just bring them up on a 20x30 luminescent 300 DPI screen hanging on the wall, maybe switching between them every 20–30 minutes or so.

"Thirty seconds after picking up an iPad, I knew the paperless future has finally arrived. We'll see the end of routine printing in the next 10 years. It's a technology whose time has passed. Honestly I get more visceral joy from looking at and handling 4x5 trannies than prints...."

Featured Comment by George Kraniotis:

"I feel the pain...every day...this image is an insect trapped

underneath the coating of a sheet of Hahmemuhle Bright White. I kept it

in order to send it to my supplier. And what about scuffing after

printing? Big issue as well. Some papers scuff just by looking at them.

Pretty sure the manufacturers can do something about this as well."

Featured Comment by ed nazarko: "I sell a lot of very large panoramas—12x144 inches, 18x180 inches—and my biggest cost and time waste comes from flaws in the paper. I usually print on smooth fine art, which hides flaws very well, better than fiber or semi-gloss papers, and I'd guess that I have to print an image at least twice to get one yielded. If I'm lucky, the flaw shows up early in the print and I can kill the job and only lose that little bit of paper. (Yes, I sit there monitoring...a hateful process, but the savings in paper costs are huge.) There have been a few papers where I couldn't get a single clean print done (I don't print them smaller than 12x144). I tried fiber or semi-gloss coated papers last year, and the yield was so bad I'm sticking with smooth fine art. I love the extra color and punch of the fiber papers, but couldn't get my head around how many failed prints I'd have to accept."

My search for a decent inkjet paper has ended with Moab Colorado Fiber Satine. I'll admit to printing mostly B&W but this paper is superb for what I do.

Posted by: MJFerron | Thursday, 29 April 2010 at 02:26 AM

I guess when photography was still done the traditional way, companies mostly had to deal with professionals or enthusiastic amateurs.

Both knew what to look for in a paper and where paying attention to it.

Nowadays though, I guess the huge majority of the paper for printers is going to the Average Joe printing pictures of his children's last birthday party.

So I would say they can get away with it because their economic base most of the time wouldn't notice or care.

Posted by: Patrick | Thursday, 29 April 2010 at 03:00 AM

I thought it was just me! Honestly.

Voltz

Posted by: V.I. Voltz | Thursday, 29 April 2010 at 04:28 AM

I know a fellow who's doing a 16"x60" inkjet print right now and these kinds of problems are driving him nuts. It seems like every print he does has some sort of flaw. He has tried to check the paper ahead of time with a magnifying glass, but as he is using roll paper he invariably kinks it during the process. The solution he's come up with is that he's marking flawed prints as proofs to exclude them from his final run, and donating the proofs for display at a few local schools to hang in classrooms. After five initial prints to get the color and tone how he wanted it (all of which he felt he needed to destroy to protect the value of his final run) he's now producing about two good prints for every flawed one. His materials cost, then, is 150% what it ought to be.

I'm find it interesting that you're posting about printing issues. Although there is a lot of discussion online about color workflow, I haven't seen much about printing issues like choices of paper and ink independent of the printer, printing maintenance and hazards, or any other non-software printing issues. Good prints are a whole lot more involved than just making sure your display is calibrated, but most of the information I've seen online fail to address the reasons that a quality print can take days to produce, even if you're working with a print-ready image.

Posted by: Aaron Scott | Thursday, 29 April 2010 at 05:28 AM

Ctien,

Surely some brightspark at HP or Epson should build a scanner into the printer to check for these defects BEFORE print.

Some HPs from memory already do the self calibration by scanning what they have printed. This would be the next natural step (especially for pro printers).

Pak

Posted by: Pak | Thursday, 29 April 2010 at 06:25 AM

So what do the paper manufacturers say when you complain to them?

Posted by: Lars Clausen | Thursday, 29 April 2010 at 06:59 AM

Just a thought -- why not embrace defects as happy accidents that turn each otherwise-identical photograph into a unique object?

In fact, a so-called defect may well enhance the image reproduced in Figure 3, the principal theme of which (by my reading) is the beauty of nature's accidents.

Posted by: Yuanchung Lee | Thursday, 29 April 2010 at 07:45 AM

For fiber inkjet, I'm using Ilford Galerie Gold Fiber Silk almost esclusively, and NEVER experience any of these problems. However, it scuffs very easily, and I am perfectly capable of imparting my own damage to it. But treated carefully, it shines.

Posted by: John Sarsgard | Thursday, 29 April 2010 at 07:52 AM

Hahnemuhle Photo Rag is not any better. As many of my images have large highlight areas, any fiber artifact, no matter how small, can ruin a print. With 17x22 paper, that can cost me $8-$9 per print, plus the wasted time.

I try to find imperfections and sequester those sheets for use only with heavily textured images, but many times the problems are not noticed until printed.

Posted by: Chuck Kimmerle | Thursday, 29 April 2010 at 08:12 AM

Have you tried contacting Harman? They are usually very good at support. Having visited the Harman/Ilford factory and seen the lengths they go to with QCing their film and traditional darkroom fibre papers like Ilford Multigrade MGIV FB, I'm surprised that there is so much trouble.

Posted by: Mike | Thursday, 29 April 2010 at 08:21 AM

Thanks Ctein, I've added this as item #173 in my list of Reasons why Miserere does not make his own prints. :-)

Despite the smiley face, I fully understand your problem and commiserate with you. I'm a perfectionist when I DIY something (as I suspect you are too) and would also be driven nuts by this type of issue.

Like Lars, I would like to know what the paper companies say when you complain to them. Furthermore, what do you do with the bad sheets? Do you use them for proofs and tests? Maybe the paper companies could sell two levels of quality for each paper type: one with 100% good sheets, another with 100% guaranteed faulty sheets.

Posted by: Miserere | Thursday, 29 April 2010 at 08:26 AM

I blame modern management technique. Us poor engineers are "organization optimized" to the bone so we've not the time or staff to get the work done. I bet every production or manufacturing plant (irrespective of product or industry) is running on the ragged edge of barely acceptable quality.

If only they'd take away the crappy admin, the endless "initiatives" and give me a couple of decent staff.

Posted by: Martin Doonan | Thursday, 29 April 2010 at 09:39 AM

Ctein, this is a perfect example of why I look forward to your weekly columns.

Posted by: Roberto M. | Thursday, 29 April 2010 at 09:43 AM

I had a vinyl recording of Elton John's Rocket Man that had a steady hard beat sound that matched the music perfectly for a few bars. Turned out it was a scratch but I didn't know for months. The first time I heard the tune at someone else's house, I thought there was something wrong with their record.

Makes me wonder what else we think it normal that maybe we shouldn't.

Posted by: Robert Roaldi | Thursday, 29 April 2010 at 09:47 AM

Part of the problem, of course, is extortionate ink prices set by the printer manufacturers. When it costs $2 in ink -- ink! -- to make a single print, someone is being robbed. And, as you point out, it means even free paper is no longer a bargain if a print is wasted.

Posted by: Bob Keefer | Thursday, 29 April 2010 at 10:33 AM

For me, as well, this is another convincing and helpful argument for the economics of professional printing vs DIY (recalling a recent TOP column about the troubled HP B9180).

These kinds of articles may seem rather specific and personal and techno (OK, they are those things), but they also illuminate important aspects of current photographic praxis that are not much discussed in public, and certainly underreported. IMO, that's good journalism, in a field that doesn't seem to have much, and something that TOP doesn't get enough credit for.

But wouldn't at least naming the names of papers and brands be a start to holding feet to the fire?

Posted by: robert e | Thursday, 29 April 2010 at 10:39 AM

Hmm. This must mean that most of the customers probably don't care. That is, for all the Ctein's and Michael Reichmann's (to pull out another name of someone who probably really cares about this*) there must be many more folks who just like printing big pictures of their cats and use the paper "recommended on some website." So the manufacturer's are under no pressure to improve things.

*Interesting that given all the reviews of papers on Luminous Landscape, that this issue has not come up. You should cross post this on that site, Ctein.

Posted by: KeithB | Thursday, 29 April 2010 at 10:50 AM

Many of the ways these flaws originate, it seems to me, will give them an equal probability of being in every square inch of paper coming out of the plant. So the chance of a sheet having a flaw would be linearly related to the area of the sheet. Bigger sheets would be defective more often, in proportion to their size.

I suspect some of my prints have flaws I haven't noticed.

What do the oil paints to make a single painting cost? Of course, even if it's in the same range as the inks, one could consider both to be extortionate. I don't actually know the profit margin on either.

Posted by: David Dyer-Bennet | Thursday, 29 April 2010 at 11:00 AM

Terrific article. Haven't had the problem but can really feel the pain. Mike's story reminded me that of buying three copies serially of a moody, dark electric guitar track as a 12" vinyl single and finding the first two unlistenable when the echo and reverb, which should have been all that you heard between the plaintive guitar phrases, were fighting a repetitive noise that sounded like someone saying "Sshh!" over and over again. The second time I returned a copy, the shop owner put it on her turntable, listened to it and told me firmly that it was a seashore backing. A seashore backing! I timed it—the "waves" were rolling in at 45 bpm. She wouldn't budge. I took an immature but very real pleasure (as a teenager) when the shop slowly declined and eventually closed over the next couple of years.

On the flip side, finding really good vinyl in the 80s was such a treat… the problem Ctein describes here doesn't have that silver lining. It's a craftsman's material, not a consumer item. He's right to expect much, much better quality than this at this level.

Posted by: Bahi | Thursday, 29 April 2010 at 11:11 AM

I'm waiting for my back ordered Inkaid to come in so I can print on scuffed aluminum flashing and brush textured spackling

compound. No worry about defects on this media.

Posted by: Mark Janness | Thursday, 29 April 2010 at 11:14 AM

Is poor quality consistent across manufacturers?

If there is a paper manufacturer that has higher quality, and people buy from them, maybe the poor quality manufacturers will get the message.

Posted by: scotth | Thursday, 29 April 2010 at 11:20 AM

I blame modern management technique. Us poor engineers are "organization optimized" to the bone so we've not the time or staff to get the work done. I bet every production or manufacturing plant (irrespective of product or industry) is running on the ragged edge of barely acceptable quality.

If only they'd take away the crappy admin, the endless "initiatives" and give me a couple of decent staff.

This is a scary thought, and all the more scary because I'm scared he's right...

Posted by: Peter | Thursday, 29 April 2010 at 11:34 AM

Just a thought: if these subtle hard-to-detect defects are white-on-white, would examining the paper under a black light perhaps illuminate them? I'm thinking that if the defect normally only becomes visible after ink is applied (different absorption?), perhaps it would also become visible under the black light.

Gordon.

Posted by: Gordon Runkle | Thursday, 29 April 2010 at 11:56 AM

I have bought MANY boxes of Epson Fine Art Velvet 17x22 at about $120 a box. 90% of the boxes I have bought contain sheets that have some bent / dinged corners. Its easy to see how this would happen because the external cardboard packaging is just to thin. Why do I put up with this? To my knowledge, there is no other paper on the market that suites my very particular needs.

Posted by: Jeff in Boston | Thursday, 29 April 2010 at 12:36 PM

Oh my. I guess I'll need to inspect sheets more carefully. Honestly, off-hand I can only recall encountering two instances of paper manufacturing defects. I must not be looking closely enough.

But, on the other hand, do I really need one more darn thing to be snarled over? Naw.

(But now it's become a Where's Waldo challenge to find the embedded pubic hairs. Darn you Ctein.)

Posted by: Ken Tanaka | Thursday, 29 April 2010 at 12:48 PM

I'll second the opinion on Ilford GFS. I buy the 50 sheet 13X19 and find very few defects. I do routinely set a print aside VERY CAREFULLY and let it dry and set for 1 or 2 days before matting or putting into a portfolio.

Posted by: Steve Greenwood | Thursday, 29 April 2010 at 01:15 PM

Some years ago I took a class in Continuous Quality Improvement. The Japanese were credited as the first country to seriously embrace this philosophy in their manufacturing.

An annecdote that was told in the class was that an American firm that was frustrated by defects in some of their products and decided to outsource the item to a Japanese company. In the contract they specified that they would accept only 3 defective parts per thousand.

The Japanese supplier sent the response, "Would you like the defective ones packaged separately?"

Leland Davis

Posted by: Leland Davis | Thursday, 29 April 2010 at 01:46 PM

Perhaps zapping the paper with an Ionoclast Ion Generator and an anti-static brush might help to remove the debris? Another cross-fertilization between audio and photography.

Posted by: Eric Chin | Thursday, 29 April 2010 at 03:06 PM

Have you observed a different incidence in sheet paper vs. roll paper (measured say by defects per square inch)? The manufacturing ought to be pretty much the same, with the handling getting more complex for the sheet paper at the end (which might lead to more scuffs, but it should be too late by then to get things embedded through the coating and such).

However, the roll paper would seem to be NOT something sold into the casual "pictures of my cat" printing market. On the third hand I'm not sure 17x22 sheets are either.

Just nibbling away at the edges, seeing if we can find any differences.

Posted by: David Dyer-Bennet | Thursday, 29 April 2010 at 03:15 PM

Perfection is impossible, in my opinion. Why strive for it?

Instead, just look at these things as part of photography, a fibre on the paper reflects the fact that the paper was made by humans and thus is not perfect. And that's ok.

Posted by: Paul | Thursday, 29 April 2010 at 03:16 PM

I've been thinking about this since the Snow Leopard and printing issue was raised: why not start a systematic and relentless letter writing campaign? Every day/week we all send the offending party a well crafted, sincere, well-mannered but pointed letter or email.

I, however, am not volunteering to write said missive but I will participate. BTW I'm a Mac user who hasn't upgraded to SL, whew!, and I have to say I haven't noticed the above mentioned flaws, yet. So I don't really have a dog in this fight, and I don't think of myself as a great writer, particularly for this kind of project.

Posted by: Dennis Allshouse | Thursday, 29 April 2010 at 04:17 PM

I'm ready for the end of paper myself. . .

I have about 100+ fine art nature prints from some of the top landscape photographers around sitting at home piled in a closet. And they are beautiful, and I love them, and bring them out every month or two just to savor the beautiful images. But I'd enjoy them even more if I could just bring them up on a 20x30 luminescent 300DPI screen hanging on the wall, maybe switching between them every 20/30 minutes or so.

Thirty seconds after picking up an iPad, I knew the paperless future has finally arrived. We'll see the end of routine printing in the next 10 years. It's a technology whose time has past. Honestly I get more visceral joy from looking at and handling 4x5 trannies than prints. . .

Posted by: Matthew C. | Thursday, 29 April 2010 at 04:25 PM

Ctein,

Our friend Michael Reichmann is now recommending Canson Baryta Photographique. Have you tried that? I gave up on the Harman FB Al.

Cheers,

Chris

Posted by: Christopher Lane | Thursday, 29 April 2010 at 04:35 PM

Nice to know I'm not the only one who frets about these things! Just printed up an exhibition and like the rest of you wasted a couple of sheets of A3 plus ink before noticing flaws, even with careful checking - just have to hope sales are enough to cover the losses!

Posted by: Tino&Pip | Thursday, 29 April 2010 at 05:01 PM

to Leland...

and Deming (an American, by the way), who taught the Japanese these quality principles, is probably rolling over in his grave about Toyota.

Posted by: Jeff | Thursday, 29 April 2010 at 05:07 PM

Mike

The quality of vinyl discs which you commented on is probably the single greatest reason why CDs came to dominate the market so completely. Other things such as the distortion inherent in analogue disc playback etc. were of less (but by no means insignificant) importance. One of my most treasured CDs is Elizabeth Schwarzkopf's recording of Richard Strauss's "Four Last Songs" but I never had that recording on LP. After returning four or five pressings to EMI, and receiving replacements which were just as bad (or worse) I gave up on the recording. When CD came along I was able to hear it as the artists and recording engineers intended.

Posted by: David Brookes | Thursday, 29 April 2010 at 05:38 PM

I do all my printing on Epson's "Ultra Premium Presentation Matte" (formerly "Ultra Premium Enhanced Matte" and before that "Enhanced Matte" and before that "Archival Matte" — seems to be the same paper, maybe Epson is in a race with Canon somehow over absurd product names … ).

I use it not because think it's the best paper — there are at least half a dozen I prefer more (the usual suspects) — but because it's the most reliable QC-wise, i..e., fewer wasted prints, and lower cost to begin with too.

I still find myself throwing out more than I'd like.

Considering that chip makers can manufacture a product with tolerances measured in nanometers, you'd think paper manufacturers could manage a mere micron or two.

Posted by: Richard Howe | Thursday, 29 April 2010 at 05:40 PM

I find with Epson Traditional/Exhibition a fair proportion of sheets out of the box have little black dots. I examine and then set these aside until I can line up the dot with a correspondingly dark area of the image. This master printing.

For warm prints I agree with others that Ilford GFS is the way to go.

Posted by: grant | Thursday, 29 April 2010 at 05:41 PM

Not too long ago I bought a few boxes of Harman FB AL Glossy from Adorama that arrived with bent corners. I contacted Adorama and they promptly shipped out replacement boxes. Maybe if more people complained about these issues they would be addressed.

Posted by: KC | Thursday, 29 April 2010 at 05:51 PM

David,

I was the same way with classical piano records. Gilels' "Waldstein" on CD...ahhh. The record on the other hand seemingly could pick up pops and ticks just sitting on the shelf.

Mike

Posted by: Mike Johnston | Thursday, 29 April 2010 at 06:18 PM

I am a big fan of Epson Traditional paper which in the USA is called exhibition I think and this has a big problem of debris on the sheets from the cutting process I guess. I have to 'dust off' the paper before printing, this happens on both the A2 and A4 sizes!

Posted by: Peter | Thursday, 29 April 2010 at 06:29 PM

Quality control results from scientific, statistical methods, but is also affected by cultural values. I'm pretty certain, observing American life as an immigrant over three decades now, that the insistence on quality that we used to have is no longer as uncompromising as it used to be. Everyone is more interested in saving a buck and getting great deals nowadays, more than ever before.

The Japanese are still fanatics about quality (I learned this when I lived there for a couple of years and was routinely amazed by the perfection achieved by ordinary drugstore prints).

Without specifically naming any other societies, I can think of at least some where the tolerance for defects is higher-it shows in the quality of manufactured goods.

Posted by: Mani Sitaraman | Thursday, 29 April 2010 at 07:44 PM

As regards for using LCDTV to replace paper, may be for one moment it is ok to have a walled picture of LCD TV displayed a great Ansel Adams I guess. But 24 hours 7 days per week like a normal picture we hang on the wall? I bought but never put even the LCD picture frame as I cannot even stand my own family album display like this. I am happy enough those faded color picture of my sons on the shelf and on the wall instead.

The future like those in "Total Recall" may be with us one day -- where you eat breakfast with LCD TV on all the windows so that you think you are in the Alps. But that future is not good.

Better paper please!

Of course they takes a bit time to come, I am still waiting for Ctein's first delivery but I am patient. I really have no need to have him click a button and I have that picture the next moment in my LCD TV. I am not an advertisement director. I am a fan only.

Posted by: Dennis Ng | Thursday, 29 April 2010 at 07:48 PM

I worked for a coated paper manufacturer for thirty plus years. These suggestions will not help with correcting the poor quality paper that is out there, it may help you not spend more money by putting expensive ink on defect ridden paper.

What we did to look for defects was first to look at the surface of the paper at a very shallow angle. Hold the paper up in front of your eyes and look across the top of the sheet with a glancing light. This is a good way to look for scratches and foreign material. Some foreign material can be brushed off and some is inside the coating or the paper and can not be removed.

Second, if you shine a UV light source, a blacklight, onto the paper, this will make many defects jump off the paper at you. This is a good way to look for the white defects. These are most often dried coating that falls back onto the paper while it is being manufactured. This is nothing but poor housekeeping.

By using a UV light you will also know if the manufacturer was using any optical brightener in the paper. The UV light will cause the paper to glow if there is optical brightener in it. If optical brightener was used, the brightness you see when the paper is new will fade over time as the optical brightener, a special type of dye, fades.

Hope this helps.

Posted by: Knapp Hudson | Thursday, 29 April 2010 at 08:36 PM

"there must be many more folks who just like printing big pictures of their cats and use the paper "recommended on some website.""

I don't really get comments like this. It seems like everyone loves to look down at the poor, dumb schlubs who are dragging everything down for the rest of us.* But who are these supposed thousands of people who are buying pigment-based printers and printing on expensive fiber-based papers so so they can make big prints of their cats? Who are these people who are so utterly clueless that they are willing to accept any kind of garbage without any protest? Sorry, I don't think anyone gets into this kind of printing casually. People buy these printers and papers because they are at least serious enthusiasts, and a lot are likely professionals. I think the real culprit is the fact that people (i.e., all of us) just don't know any better and tend to assume user error or that what we get is the best that is currently possible. I'm reminded of an earlier post by Ctein (which I can't find right now, despite spending half an hour looking) about a batch of defective film developer where nobody complained to the manufacturer although their film was ruined. If you want to blame someone other than the manufacturers, then everyone should look in the mirror before pointing fingers at those mythical bumbling dentists who take pictures of their cats with their M9s.

As for the second part regarding people who "use the paper recommended on some website", I plead guilty. There appear to be hundreds of different papers out there. I do not have the time, the money or the patience to try all of them. So I tried a handful of the ones that generally seem to receive the most positive reviews and left it at that. Why shouldn't I leverage the knowledge and testing efforts of those who know more about this and have done more comprehensive tests than I can or will do? If a reviewer recommends a paper and my results are complete crap, I'm not going to keep using the paper just because it was recommended. But if the results are good, then I see little reason to test another 50 different papers in search of something better (though I am likely to test another 3 or 4 just to check what other looks are available).

Best regards,

Adam

*I may be a touch sensitive to these kinds of comments today, given a few knocks I have taken on an unrelated website.

Posted by: amcananey | Friday, 30 April 2010 at 06:06 AM

All is not well in the traditional paper world either: http://photo.net/black-and-white-photo-printing-finishing-forum/00VtRu?unified_p=1

I almost fell off my chair when I saw who posted the query above. It was impressive to see how quickly she got help, but I think she has earned the extra attention.

Posted by: latent_image | Friday, 30 April 2010 at 07:13 AM

I have had the same problem with bent corners on Epson VFA, which I love--yet I confess I have never complained about it and hence am part of the problem. This thread has stiffened my resolve to holler when consumables arrive damaged.

Part of this is the web-based buying experience. It seems cheaper and more efficient, but you are very removed spatially and temporally, from the source.

Posted by: Don Jagoe | Friday, 30 April 2010 at 07:19 AM

The absurd price of inkjet papers deserves more attention. It is ridiculous that a mediocre quality paper with no silver in it should cost as much or more than a high quality paper WITH silver in it.

We are being cheated by these manufacturers of inkjet papers and an organized campaign to make them stop would seem to be in order.

How about picking one manufacturer to "set an example" and simply agree that no papers will be bought from that manufacturer. Publishing a list of manufacturers who will receive the same treatment, in the order they can expect to receive it, ought to straighten out at least one or two of them.

Posted by: fmertz | Friday, 30 April 2010 at 09:18 AM

The Japanese are still fanatics about quality (I learned this when I lived there for a couple of years and was routinely amazed by the perfection achieved by ordinary drugstore prints).

Sorry to stereotype, but I got a similar impression of the Germans, at least where I was living for a few years.

Posted by: Peter | Friday, 30 April 2010 at 10:00 AM

If I could add one more comment to this "old" topic...

While I have not encountered the frequent manufacturing defects that others report I do frequently encounter terrible shipping and handling. Off-hand I would estimate that 1/3 of my paper shipments (sheets) arrive with bashed corners. Adorama snd B&H have both been guilty of packing expensive paper as if it was last week's New York Times, often loose in a box with a deflated airbag or two. Atlex shipments have always been carefully packed and have always arrived in good condition.

So as long as we're spraying peeves, mine is s&h of resellers.

Posted by: Ken Tanaka | Friday, 30 April 2010 at 10:46 AM

Sorry Adam, I did not mean to offend. Especially since I am probably just as guilty of the sin I am complaining about, being more hat than cattle in the photography arena. My point was simply that if the market does not demand better quality from the manufacturer, better quality will not come.

And that is where articles like this are so important. I seem to recall a spreadsheet on LL discussing printing costs. AFAIR, no mention was made about re-dos because of bad paper.

Posted by: KeithB | Friday, 30 April 2010 at 11:59 AM

I sell a lot of very large panoramas - 12x144 inches, 18x180 inches - and my biggest cost and time waste comes from flaws in the paper. I usually print on smooth fine art, which hides flaws very well, better than fiber or semi-gloss papers, and I'd guess that I have to print an image at least twice to get one yielded. If I'm lucky, the flaw shows up early in the print and I can kill the job and only lose that little bit of paper. (Yes, I sit there monitoring... a hateful process, but the savings in paper costs are huge.) There have been a few papers where I couldn't get a single clean print done (I don't print them smaller than 12x144.) I tried fiber or semi-gloss coated papers last year, and the yield was so bad I'm sticking with smooth fine art. I love the extra color and punch of the fiber papers, but couldn't get my head around how many failed prints I'd have to accept.

Posted by: ed nazarko | Friday, 30 April 2010 at 01:10 PM

Dear Lars, et.al.,

Haven't had chance to go beat anyone upside the head, yet. Until recently I didn't have a large enough volume to Harman paper printing done to be convinced this was an ongoing and serious problem. Now I have the data. And thanks to latent's link to Sally Mann's woes, I have the contact info I need without doing any research. Yeah, Harman's gonna hear from me.

~~~~~~~~~~~~~~~

Dear John and Steve,

A friend, Geoff Stone, had already recommended that paper to me, and I bought a small box of the 8x10 to play with. You guys are recs 2 and 3; that'll kick it higher on my priority list. Thanks!

~~~~~~~~~~~~~~~

Dear scotth,

That's hard data to come by -- you need a big statistical sample to figure out who's better and who's worse and to be sure you're not looking at a momentary fluctuation.

~~~~~~~~~~~~~~~

Dear eric,

No, the flaws are embedded in the paper. They're not removable by any means, not without scarring the surface.

~~~~~~~~~~~~~~~

Dear Gordon,

Knapp appears to have confirmed your idea. Clever! I shall have to borrow friend's black light and see how well it works.

pax / Ctein

==========================================

-- Ctein's Online Gallery http://ctein.com

-- Digital Restorations http://photo-repair.com

==========================================

Posted by: ctein | Saturday, 01 May 2010 at 11:39 PM

Dear DDB,

Yes, exactly-- it very easy to get 4x5 sheets of the Harman paper that are flawless. It's very hard to get 17x25 sheets that are. As John and ed have commented, it makes using roll paper very dicey, and it's what's dissuaded me from even trying the Harman FB Al in rolls.

~~~~~~~~~~~~~~~~~~~~~~

Dear fmertz,

While I agree the inkjet paper prices are excessive, silver content (or lack thereof) has little to do with paper prices. The value of the silver in an 8x10 sheet of B&W darkroom paper is around 3 cents at current prices. Even allowing for the normal 5X different between material costs and retail price, silver doesn't have a big impact on paper price.

~~~~~~~~~~~~~~~~~~~~~~

Dear Ken,

Oddly, I've gotten well-packed shipments from B&H and the shoddy ones from Atlex. Apparently no consistency in that part of the business, either. Sigh.

~~~~~~~~~~~~~~~~~~~~~~

Dear Michael W,

I suspect that a similar problem may exist with the inkjet paper manufacture. The raw stock for paper (as you no doubt know) comes in bales that usually have wrappers, such as cheap kraft paper. For many kinds of paper, you don't bother to strip the wrapper off the bales-- who whole thing goes into the hopper. For some papers, this is disastrous, as you discovered!

Kodak got into that situation twice with dye transfer paper, once in the early 80's and again in the early 90's. The original 'cookbook' specified that the wrappers should be removed from the bales of cotton rag before pulping, but Kodak stopped following that practice in the early 80's. A high percentage of sheets had emulsion flaws or dark inclusions that made them unsuitable for high-valued prints. The problem reappeared in the two years before Kodak discontinued the line in 1993-94.

Quality was completely impossible to predict. When sorting sheets of paper for the TOP dye transfer print sale earlier this year, I dug into two 100-sheet boxes of 11x17 paper, manufactured not too far apart in time. One box had 90% good sheets. The other had 10%.

pax / Ctein

==========================================

-- Ctein's Online Gallery http://ctein.com

-- Digital Restorations http://photo-repair.com

==========================================

Posted by: ctein | Saturday, 01 May 2010 at 11:49 PM

If any letter-writing campaign should be done, it should be one of sending in prints with flaws in them and a not saying, "there was a manufacturing defect in your paper, please replace it". Any significant volume of such letters would a) get the message across, and b) cost more to handle than it would to put proper QC in place. Also, it would hurt the worst offenders proportionaly and reward those who fix their process.

Posted by: Lars Clausen | Sunday, 02 May 2010 at 08:59 AM

I agree wholeheartedly with this article. We've accepted this situation, including the high product cost, because there is no option. Like John above, I have only used rolls when absolutely necessary for a client requiring large print size than the Iris size sheets allow. Unfortunately large sheets are being offered less and less, limited to 17x22 for many new papers. Ctein's article only scratches the surface, I have paper stories much worse, and others do as well. Sometimes these situations make being a small print shop as a business nearly untenable. I've had to throw jobs out hours before the clients is expected, recently one quite large...

I've been using more and more Canson, and quality control looks good so far, but the prices... well, I have to consider raising my prices in an economy in which all of my artists are hurting.

Just wanted to add my voice of support for this issue, it's been too quiet.

Tyler

Posted by: Tyler Boley | Sunday, 02 May 2010 at 02:22 PM

Great article! Sometimes you will have paper manufactures that will produce less than stellar paper. It really becomes a serious issue when you are working on important projects that require perfection. When this type of issue arises, you can either deal with or take it to a professional.

Posted by: Arian | Tuesday, 04 May 2010 at 04:07 PM