By Ctein

Here's a coincidence. When Mike wrote his column about the craft of black-and-white darkroom printing two weeks ago, to the applause of film photographers who felt they were becoming depraved on account of being deprived, I was already in the midst of writing this column on the craft of black-and-white darkroom printing. Great minds running in the same gutter, I suppose.

Then Mike made me an offer I wasn't about to refuse (two weeks off) and so here we are.

One of the modest burdens that photography writers and editors have is revisiting basic topics. It always annoys advanced readers to see yet another article covering Something 101. I know it annoyed me. But it's necessary, because everyone doesn't absorb the message the first time, there are always new people coming into the field (yes, even black-and-white film photography today), and every single person on the planet does not read every single word we write.

Yes, I know that last one is a real shocker. Don't we have the ear of the entire universe?

Anyway, this is one of those basic topics.

A reader of my book Post Exposure (available for free here) wrote me asking if it was important to have a print washer whose water entered from the top and exited from the bottom, because fixer was heavier than water and would sink to the bottom of the print washer.

A lot of people have thought that, including some otherwise extremely knowledgeable darkroom folks.

It doesn't work that way.

Yes, fixer has a higher density than water (density is what counts, not weight). Pour it very carefully into pure water and it will sink to the bottom. It won't stay there. There are countervailing forces at work. Gravitational potential energy drags the heavier stuff down. But diffusion/entropy/statistics favors mixing everything up uniformly. They compete. On a molecular scale, diffusion almost always wins.

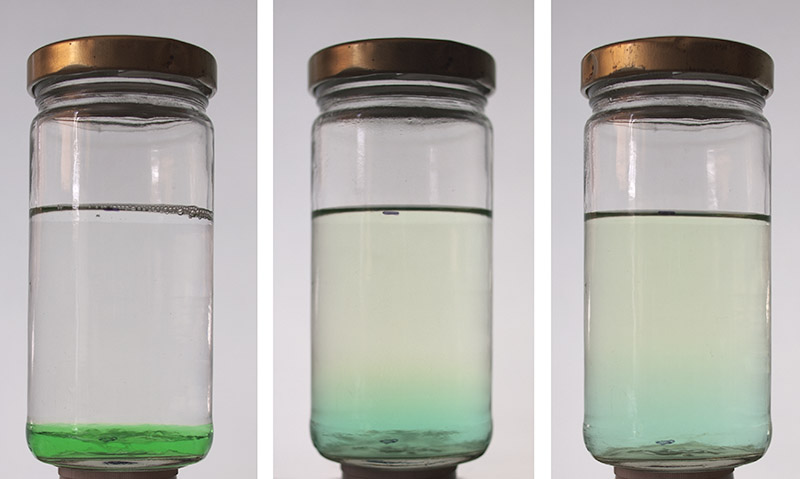

I recapitulated an experiment from elementary school science (at least, when I was in elementary school). I squirted a heavy liquid into a jar of water. I used dish detergent, but sugar syrup will work just as well. I was careful not to move it much so there was very, very little water circulation going on. The left-hand picture shows what it looked like at the start. The middle picture shows the jar after it sat on my desk for four days, and the right after 10 days. Notice the direction of motion is not downward.

Conversely, if I had started with a mixed solution, the denser stuff wouldn't have settled out*. As I said, the same trick will work with sugar syrup. I don't think any of you have noticed that if you open a long-standing container of soda it tastes bitter at the top and excessively sweet at the bottom, because the high fructose corn syrup settled out.

You'll notice this took a fairly long time; diffusion is a very slow process. Still, it was enough to overwhelm gravity. Imagine what would happen if I stirred the container at all. Even, say, once a minute with just one twirl with a swizzle stick. Very quickly, all that dense detergent would go into solution. Even the most modest circulation of water works much faster than diffusion or gravity work all by themselves.

Which is the whole point behind a flowing-water print washer. The idea is to keep fresh, relatively uncontaminated water near the surface of the paper so that fixer can diffuse out of the paper as quickly as possible. It doesn't matter which way the water is flowing, up, down, or sideways. Even slow flow is much faster than all the competing processes.

You can wash prints, even fiber-base ones, in (mostly) stationary water, and people who have to be extremely water conscious or don't have a running tap in the darkroom can do this. You give the print a quick rinse in a holding tray, maybe 15 seconds sloshing it around; that gets rid of perhaps 90% of the fixer, all of the relatively concentrated carryover. Then you move the print through a series of standing trays of water, half a dozen is sufficient**, agitating the trays on occasion. Just let the fixer diffuse out of the paper into the surrounding water. My recollection is that it takes two to three times longer than vigorous water changes in a flowing water print washer, but it's a very conservative of water. Taken to the extreme, you can thoroughly wash a print in ounces of water rather than gallons. No, I don't have a good citation at hand for the precise procedure and it's not in my book, but I'm sure one of the readers here can come up with a pointer to a tutorial.

Back to the science for a bit. This is one of those instances where size matters. Mix gravel into water and it sinks immediately. Mix sand into water and it sinks very quickly. Silt will take days. Fine rock flour has small enough particles that some of them will remain in suspension forever. Like those fixer molecules.

Not so irrelevantly, if you change the balance of the forces, you get different results. Make gravity much stronger, and you can overwhelm the countervailing diffusion effect. Behold the centrifuge. A centrifuge not only will make stuff fall out of solution faster, it can extract stuff that would stay in suspension indefinitely under one gravity.

Ctein

Ctein, author of well over 500 published articles for many different photography magazines, writes a weekly column for TOP that appears on Wednesdays.

*[Ed. Note: This was the direction of Phil Davis's experimentation when he sought to disprove the same myth. He simply mixed equal parts fixer and water, shook the jar, then let it stand on the shelf in his darkroom for a year. Then he carefully sampled the contents at the top and bottom of the jar. No difference—the solution was still uniform.]

**[Ed. Note: I believe David Vestal's experiments proved that three—or was it four?—changes of water is sufficient.]

I read this as : "fixer doesn't stink". And it does!

Posted by: Keith Loh | Wednesday, 13 July 2011 at 03:41 PM

If I remember correctly, that fixer myth goes back to the late Fred Picker and could be found in the pages of the Zone VI catalog with their washers (which work fine regardless). That is probably the reason it is so widespread.

Posted by: Arne Croell | Wednesday, 13 July 2011 at 03:41 PM

Well, that certainly added to my OC behavior for the day; and in that spirit, fixture should probably be fixitive. 8-)

Bron

Posted by: Bron | Wednesday, 13 July 2011 at 04:03 PM

"that fixer myth goes back to the late Fred Picker and could be found in the pages of the Zone VI catalog with their washers"

True.

Mike

Posted by: Mike Johnston | Wednesday, 13 July 2011 at 04:04 PM

Or hypo.

Bron

Posted by: Bron | Wednesday, 13 July 2011 at 04:10 PM

To follow up on the concept of needing to repeat the basics, I remember reading a quote from a physician teaching his students that went alon the lines of "I have to fight my urge to skip the basics or just gloss over them because this might be the first time the student has heard it."

Seems appropriate here, too.

Posted by: John D | Wednesday, 13 July 2011 at 04:16 PM

Well, well ... Some 40+ years ago I acquired a second hand sheet film back for my Rolleicord Vb, together with three sheet film holders (cassettes?). Anyway, the memory Ctein's column brought back to my mind, is of a bucket full of water, with a piece of rope strung tightly across it on top, and on the rope is a clothes-peg, holding one processed sheet film ( a b&w negative), just so that it is immersed in the water. All I needed to do then, was let it sit there for an hour, and then take the negative out and dry it. I was convinced it was now well rinsed and totally devoid of fixer, as the fixer would have firstly diffused and secondly sunk to the bottom because of its weight. Unfortunately, all (not a great many) negatives from that era are lost, so I can't check their stability now. But at the time (at age 19 or 20) I was convinced that this procedure was as practical as it was effective. Live and learn!

Posted by: Hans Muus | Wednesday, 13 July 2011 at 04:21 PM

What is fixer? And won't washing my prints wash out all the ink colors out too?

TFIC,

Gordon

Posted by: Gordon Lewis | Wednesday, 13 July 2011 at 04:23 PM

The big problem is the whole "washing" concept. People get visions of laundering their prints and worry about getting enough agitation and end up damaging their prints from all the thrashing.

I used to wash 50"x80" prints by moving them between a pair of 60" stock troughs (things cows drink water from) 3 times. Didn't save much water though, must have been at least 50 gallons of water in each change.

Posted by: hugh crawford | Wednesday, 13 July 2011 at 05:03 PM

I think it's a brilliant idea to revisit the 'old' topics. It's especially nice to see this one done well -- short and sweet, with illustrations :) Thanks.

Posted by: dwross | Wednesday, 13 July 2011 at 05:11 PM

If I recall my chemistry correctly, isn't the issue based entirely on the chemical difference between a solution and a suspension? Put salt water in a centrifuge and no amount of spinning will separate the salt out (unless the solution is supersaturated, in which case it is actually both a solution and a suspension). But the very finest silt suspended in water will be separated out in the same centrifuge because it is only suspended - it does not chemically dissolve in the water. Fixer in water becomes a true solution. Isn't that just what Ctein was saying?

And I also remember having this same discussion when I first read Fred Picker's catalog so many years ago.

Posted by: Rick Donnelly | Wednesday, 13 July 2011 at 05:23 PM

I think I remember an article in Amateur Photography, probably in the 1960s, that persuaded me to always rinse my B&W films in this fashion, with 5 rinses, each perhaps 2 minutes, because I could do it from one bucket of clean water at the right temperature.

Temperature controlled mixing valves were too expensive for me, and I'd lost at least one film to reticulation, due to rinsing in fresh water from the tap that was too cold.

The article said that film rinsing was very much a diffusion limited process - I think the author had done some chemical tests (titration?) to prove the sufficiency of this method. My old B&W negs rinsed this way seem to be OK so far.

Posted by: John Ironside | Wednesday, 13 July 2011 at 05:29 PM

I love reading stuff like this. Brings me back to when real photographers printed their own pictures. Did I miss the part about how to calculate correct fixing times? The labels always quoted minimum times. I would conduct test-strips for fixing. Have 3 strips of Ilford Multigrade or Galerie. Fix one for 60 seconds, one for 90 seconds, one for 110 seconds or whatever...then into the stop-bath...then wash...then into the developer and Turn on the lights! Watch the clouding in the strips. and so you have the correct fixing-time. "real photographers print their own pictures". These days I have a digital workflow and use the same mind-set...or, at least I hope so. We never used to look for the next great camera.....!

Posted by: ben ng | Wednesday, 13 July 2011 at 05:32 PM

"You can wash fiber-base prints in (mostly) stationary water . . . Then you move the print through a series of standing trays of water, half a dozen is sufficient . . ."

I remember in college honors chem proving mathematically that several very small, brief rinses were more effective than one very large, 'through' one. I don't remember the proof any more, all these decades later.

Then we did empirical tests that proved the proof.

Must have been good stuff, as there is now a building on campus named after my then teacher.

Moose

Posted by: Moose | Wednesday, 13 July 2011 at 05:51 PM

One of the great pleasures of this site is that even a non-darkroom affectionato can read an article on "fixer dilution", and enjoy quality of the content and the writing. (After the TOP articles, I actually would like to have a B&W dkrm., but alas no space for it.)

Posted by: Alex Vesey | Wednesday, 13 July 2011 at 06:16 PM

May I recommend an article to be found online called 'Mysteries Of The Vortex' (Parts One and Two) by Martin Reed of Silverprint. Find it through searching one of the forums such as FADU (film-and-darkroom-user.org) or apug.org. The article is an excellent exploration of archival print washing technique and explains why slot type archival washers are a worthwhile investment.

I think that it was just 3 changes of water at an hour each, unless I am confusng it with someone else who came to a similar conclusion, i.e. that it worked. The darkroom forums still seem to have a healthy growth of new members and print washing is still much discussed.

(I've been using alkaline fixer for a couple of years and find it takes less wash time and cuts out any need for hypo clearing agent).

Posted by: Mark Walker | Wednesday, 13 July 2011 at 06:53 PM

"No, I don't have a good citation at hand for the precise procedure and it's not in my book, but I'm sure one of the readers here can come up with a pointer to a tutorial."

From the Ilford web site:

"WHAT IS THE ILFORD PHOTO ARCHIVAL SEQUENCE?

The ILFORD PHOTO Archival Sequence is a method of processing fiber base papers for maximum longevity while reducing the amount of water and time used.

The method, which was fully tested more than a decade ago, requires the use of a non-hardening rapid fixer mixed at film strength.

After the paper has been developed and stopped, it is placed in such a fixer for 60 seconds with intermittent agitation.

Next the paper is placed in a running wash for five minutes, followed by an immersion in ILFORD PHOTO Wash Aid (1+4) for ten minutes with intermittent agitation.

The end of the sequence requires an additional five minute running wash."

Posted by: Kevin | Wednesday, 13 July 2011 at 07:13 PM

And as a side note, the only "tool" I regret selling, is the wet dark room. Not enough to buy another, but far more than the woodworking planes, power tools, cameras, etc.

If I had had it, it would be functional, though primative, today. I'd probably still have a film camera, tri-x, just because I could do it.

Ahh, well, it is tough when bills need to be paid, and B&W is far from helping pay them, but like I say, the one "tool" I regret selling.

Posted by: Bron | Wednesday, 13 July 2011 at 07:52 PM

Mark,

Glad you liked that...Martin and I and the PT staff worked very hard on those two articles.

I hope Les got permission from Martin and from PT to publish that online. It's still under copyright I'm sure.

Mike

Posted by: Mike Johnston | Wednesday, 13 July 2011 at 09:04 PM

I appreciate the washing info. Don't like wasting water. Washing though is not the hard part. Someone tell me how to dry fiber prints flat without expensive equipment?? I keep going back to RC.

Posted by: MJFerron | Wednesday, 13 July 2011 at 09:46 PM

Here's a discussion of the "Ilford Method":

http://www.largeformatphotography.info/unicolor/ilfwash.pdf

For film, one quick rinse, then 3 changes of water, with agitation, and the film is archival.

A similar, but somewhat longer, routine works for paper.

Posted by: Paris | Wednesday, 13 July 2011 at 09:48 PM

Interesting. How about fixer that's loaded with silver though? Just a wild uninformed guess, but I'd assume it'd be a tad heavier than plain ol' fixer.

Posted by: Kent | Wednesday, 13 July 2011 at 09:53 PM

"Someone tell me how to dry fiber prints flat without expensive equipment??"

Can't be done. You need a drymount press to flatten them after they're dry.

Mike

P.S. I said "can't be done." Which is also my reply to everybody who will now say, "Yes it can be done, here's how you do it...." Believe me, I've tried *every* way there is.

Posted by: Mike Johnston | Wednesday, 13 July 2011 at 10:30 PM

"Can't be done"

I kinda figured as much. Thanks.

Posted by: MJFerron | Wednesday, 13 July 2011 at 10:51 PM

Depends on how stringent your definition of "flat" is. Blotter books come closest (yes, all the issues with cross-contamination if you ever screw up even once).

Doesn't matter, though; you need to ferrotype fiber base for a decent gloss anyway, and that takes equipment that also leaves your prints flat.

Posted by: David Dyer-Bennet | Wednesday, 13 July 2011 at 11:24 PM

Dear Kevin,

The Ilford Archival paper wash is great, but it still requires flowing water, just less. I'm referring to a way to wash prints with no flowing water whatsoever, just a series of standing trays. Consumes much less water than even the Ilford method. Trouble is I don't have the details at hand.

~~~~~~~~

Dear Paris,

Film (and RC papers) wash much more quickly than fiber base papers because fixer washes out of emulsion much more readily and quickly than out of fiber paper base. The "Ilfwash" procedure is not directly applicable to paper, although the concept is the same. Problem is the devil is in the details and I ain't got the details.

pax / Ctein

Posted by: ctein | Thursday, 14 July 2011 at 12:20 AM

I was in art school (San Francisco Art Institute, to be exact) in the mid-1970s, and here in California, there was a drought going on. At school, the darkroom area asked students to conserve water by not using flowing water to wash film or paper, but to use changes of standing water. It became my MO, and worked very well. My negs and prints from that era suffer many of the faults of the beginning photographer, from exposure issues to "me-too" work trying to copy the masters and professors, but none of them show signs of chemical contamination or archival issues.

Posted by: Ernest Zarate | Thursday, 14 July 2011 at 01:06 AM

I seem to remember something about using two trays of fix , with the theory that second fresher and less silver laden fix was easier to wash out. Or was that part of a toning process or a scheme to get the most silver laden fix possible before throwing it into the silver recovery "system" which was a plastic wastebasket with a clump of steel wool at the bottom.

Posted by: Hugh Crawford | Thursday, 14 July 2011 at 02:06 AM

"Can't be done. You need a drymount press to flatten them after they're dry."

I'll second that. It's the main reason I don't make silver-based prints anymore. Drymount presses are large, heavy, and expensive. And unlike fixer, they will definitely sink if placed in water.

Posted by: Gordon Lewis | Thursday, 14 July 2011 at 06:00 AM

Questions: How much prints can I rinse in the same tray (taking in account that the tray is the size of the paper)? Or must I rinse one paper and then throw the water and fill with fresh water for the next print? If this is the method is very water and time consuming.

Can I use a tray with water to store a batch of prints to apply then the method of six trays? Usually I never printed and washed one sheet of paper each time. I print several copies and then finish the process.

I have a washing tray for running water but for fiber paper I had not consistent results. Some of my 15 or 20 years fiber prints are stained.

I side 101 comment: Fix is affected by low temperature. In the past I had my darkroom outside the house and in winter all the chemicals go to very low temperatures. When I warm up the fix don't react the same way. Was like outdated. I don't why but this happened to me. Many thanks and good prints

Posted by: Hernan Zenteno | Thursday, 14 July 2011 at 08:39 AM

Great article Ctein; especially since I've got really constrained space and access to water, so this really helps. I feel paranoid about the washing process (as I think that most advice out there is to play it safe, I guess because it's a statistically driven thing. And I say a FEEL because I don't really know!)

Here's a question: What about wash accelerators? Do you use them and how do they help?

Cheers, Pak

Posted by: Pak-Ming Wan | Thursday, 14 July 2011 at 09:03 AM

Nice technical, photo-geeky post. I love it. This discussion takes me way back to the days of a darkroom in my bedroom as a teen (what were my parents thinking?). I washed film and prints in a tray in the tub - pretty much just filling them with water, agitating, dump, refill, repeat. I still have some of those prints and they seem OK (almost 30 years now). Oh plus it reminds me of that Sprint chemical line - remember that? The blue fixer remover? That was fun.

Posted by: Gregory Wostrel | Thursday, 14 July 2011 at 09:14 AM

"If this is the method is very water and time consuming."

Hernan,

Yes, it's really for one print at a time, and you do need to use fresh water (preferably distilled, because water with a lot of minerals already dissolved in it won't allow the fixer to diffuse out as readily). And you need to make sure the print stays submerged in the water (fiber prints have a tendency to float, and if you leave them without tending for a long time, to start to dry). It's really not a good method for large batches. It still consumes much less water than turbulence washers, though.

Mike

Posted by: Mike Johnston | Thursday, 14 July 2011 at 01:02 PM

Dear Hernon,

Here's the way it's normally done. It uses what is called "counter-current flow.”

Make print A and put it into the water in tray 1

(How much water? For how long? With how frequent agitation? Sorry, those are the details I don't remember and I'm hoping some reader does.)

Leave the print in tray 1 until your next print is ready to go into the wash. Then move print A from tray 1 into tray 2, and put print B in tray 1.

After making print C, A goes into tray 3, B goes into tray 2, and the new print (C) goes into tray 1.

Keep this up until print A is in the last tray (let's call it 6). On the next print cycle, you'll take print A out to dry. After you've moved all the other prints down the line and put your newest print in the first tray, you start changing water. You dump the water from tray 1. You pour the water from tray 2 into tray 1. You pour the water from tray 3 into tray 2. And so on until your last tray. After you've back-transferred the water out of tray 6, you pour FRESH water into tray six.

If you get really good at this, you will use a lot less than 1 L of water per finished print.

You could adapt this method for washing several prints at a time, but it would be a lot more labor-intensive because you'd have to periodically interleave the prints in each tray to make sure all the paper surfaces were sufficiently exposed to "open" water rather than to each other.

pax \ Ctein

[ Please excuse any word-salad. MacSpeech in training! ]

======================================

-- Ctein's Online Gallery http://ctein.com

-- Digital Restorations http://photo-repair.com

======================================

Posted by: ctein | Thursday, 14 July 2011 at 02:31 PM

As a long-experienced engineer attending one of my lectures observed "is nice to know the basics haven't changed much".

A minor point missing from the original description of the mixing process involved is the concept of miscibility (thus surface tension effects). Try this trick with oil & water and you'll be pretty disappointed.

And I think that is whence most people's basic confusion stems - the "intuitive' understanding that comes from the more common oil/water interaction, which is normally discussed purely in density difference terms.

Posted by: Martin Doonan | Thursday, 14 July 2011 at 10:45 PM

I seem to have found a broken link on Ctein's website... what do I win? A dye-transfer print? ;)

Seriously, local gallery (http://www.mga.org.au/exhibition/view/exhibition/89) has a exhibition with several dye transfers on display. Well worth viewing if you're in Melbourne.

Posted by: Nige | Friday, 15 July 2011 at 08:06 AM

Dear Nige,

Entirely possible there's a broken link somewhere, but you're going to have to e-mail me a pointer to the page and the link. I've checked the Post Exposure page, and it's not broken nor are any of the direct links from it.

pax \ Ctein

[ Please excuse any word-salad. MacSpeech in training! ]

======================================

-- Ctein's Online Gallery http://ctein.com

-- Digital Restorations http://photo-repair.com

======================================

Posted by: ctein | Friday, 15 July 2011 at 02:28 PM

What you do to dry fibre prints without a press is this :

put the wet print on a sheet of glass, moisten some gummed brown paper strips, fix the strips to the print and the glass, then let them air dry. As they dry, the prints shrink slightly, and are held by the paper strips, so they end up perfectly flat. Cut them free of the glass and smile broadly. It works perfectly!

Posted by: Chris Richards | Friday, 15 July 2011 at 03:32 PM

Hi Mike,

Sorry, I had no clue as to the full provenance of the article, but it does have a style of eminent readability running through it for such a technical piece, so your signature is surely embedded in it.

Martin Reed is a well known regular contributor to the forum it was linked from, so I am hoping it was a legitimate link,

Thanks,

Mark Walker.

Posted by: Mark Walker | Saturday, 16 July 2011 at 03:52 PM

My first physics professor started the semester by saying:

"Entropy always wins"

On the final exam, the first question was:

"Explain why entropy always wins. Extrapolate this to the end of the universe"

This took some 'splaining"...

Posted by: malcolm | Monday, 18 July 2011 at 05:53 PM

I have some friends who are relatively respected in fine B&W printing. They tested a Zone VI print washer and had the water running at first. Then, let it sit overnight. They then did residual fixer tests of different areas on the prints. The tests showed the bottom of the prints(at the bottom of the washer) to have more fixer still in them than a the top of the print. NO indication of fixer settling, but the prints did test this way. Starting the water again washed prints clean in a half hour.

Don't know why the prints tested this way - maybe how the water circultion moves?

Posted by: Daniel | Monday, 18 July 2011 at 07:05 PM

Dear Malcolm,

Hahaha! Reminds me of a truly classic (sic) final exam in Classical Mechanics, when I was at Caltech.

Instead of handing out test questions, the professor pulls a quarter out of his pocket and spins it on the table. "Describe the motion," he says, and walks out.

~~~~~~~~

Dear Daniel,

Not entirely sure what was being tested there, from your description. Assuming the water was run enough at the beginning that the tank was pretty uniformly full of fresh, non-fixer-laden water, what you were seeing the next morning was differences in how different parts of the prints washed in those first few minutes of running water.

Remember, as my experiment above showed, diffusion moves very slowly.

It's not really an issue. No one makes a print washer that is supposed to wash each part of the print at exactly the same rate. They're only supposed to insure that after the mandated wash time, all parts of the print have sufficiently low residual fixer levels. If some part of the print happened to get five times as much washing as as necessary and another got merely just enough, no one cares.

pax / Ctein

Posted by: ctein | Tuesday, 19 July 2011 at 03:26 PM