By Ctein

My last column, published on June 20th, explained that there's lots of unit-to-unit variability in photographic gear. Recently I had reason to investigate variability in Epson 3880 printers.

Before I get into this, let me emphasize that these are great printers and Epson is a great company. I've been entirely satisfied with the quality of their goods, and their customer support and warranty on their professional printers is almost inhumanly superb. I will continue to buy Epson printers in the future, along with an extended warranty.

Further, my decades of experience as a reviewer do not give me any reason to think that my results are unique to Epson. I expect I would find similar variability if I looked at any maker's printers. In short, this is not Epson bashing, nor an excuse for such. Diving in...

Last fall my Epson 3880 printer developed a head clog. The heaviest of heavy-duty cleaning cycles did not clear it, so I called Epson support: "No problem, you'll have the replacement printer tomorrow."

The next day I did, along with the prepaid pickup label to return the old printer. Out with the old, in with the new. A quick test showed the tone and color balance were nearly identical to the old printer. I didn't even need to make new profiles. Hurray!

When I looked more closely at the new prints, they looked "grainier." The old printer produced invisibly-fine droplet patterns; I could just see the individual ink droplets in the new prints. Not so "hurray."

After doing my own version of "is it plugged in," I called back Epson support. Got this great technician who knew even more about Mac systems than I did. She suggested a couple of more plugs to check, so to speak. We fiddled around for half an hour, then she shipped me another printer. It wasn't a lot better.

I put the matter on hold for a few months. At the end the last year, I called support again; the fellow I got this time clearly didn't know much about Macs, but he spent a good 90 minutes with me on the phone as we tried to figure things out, even waiting while I made scans of sections of prints and e-mailed to him. He was pretty convinced I was seeing normal product variation, but I wasn't. So, Epson sent me a third printer.

It was a little better than the second, but nowhere near as good as my original printer. Still, I agreed that there was hardly much point in sending me further printers without having some good reason for thinking they would be better.

Me, I'm thinking thusly: I bought this really great printer in late 2010. I got three replacement printers in late 2011 and they all looked worse. Something had slipped in quality control at Epson. A slight timing jitter in the placement of the ink droplets would explain the degraded pattern I was seeing. There are ways that manufacturing can go awry that will cause that.

I put my suspicions forward to Epson. They accepted a packet of sample prints from me, which were shown to the production managers. They still thought it was normal sample variation.

I persevered. I have a private contact inside Epson, someone positioned to make things happen if there really was a problem and someone who knows me personally and professionally, so he knows exactly how careful I am about testing and making these kinds of claims. He investigated my reports and my data. His conclusion was that I had lucked into a "cherry" unit the first time. A random roll of the dice.

I still thought (well, hoped) that Epson might be wrong. I decide to test their conclusion. If I looked at prints from a whole bunch of 3880 printers manufactured at different times and found a systematic variation in "graininess" with time, that would prove that something had changed in the manufacturing process. I knew how to collect that data—crowdsource it to you, my faithful readership.

So now you know what my request four months back for people to make Epson 3880 prints was all about. People came through. I collected 40 respondents, with printer purchase dates scattered over more than a two-year period that nicely bracketed my units. Yes, I know that purchase date is not the same as manufacture date, but it correlates roughly. I had people provide me with their printers' serial numbers in case I needed more accurate dates down the line.

I provided a test file, told folks exactly how I wanted it printed out, and had them send me their prints. I ranked the prints by graininess from first/best to last/worst. I plotted those rankings against the purchase dates, confident a pattern would emerge. I didn't know if I'd see a gradual degradation in quality with time, or a relatively sharp transition when something changed in the manufacturing line, but I expected there'd be something.

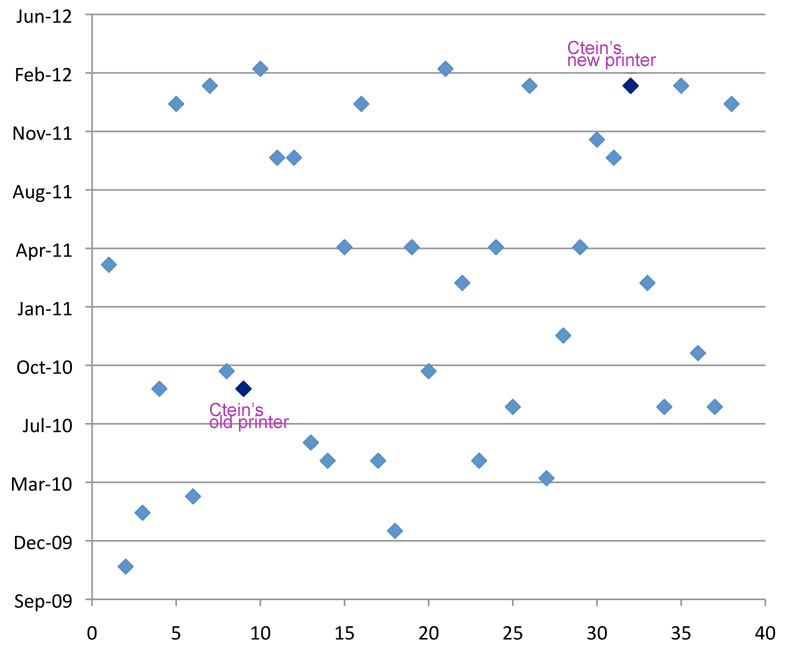

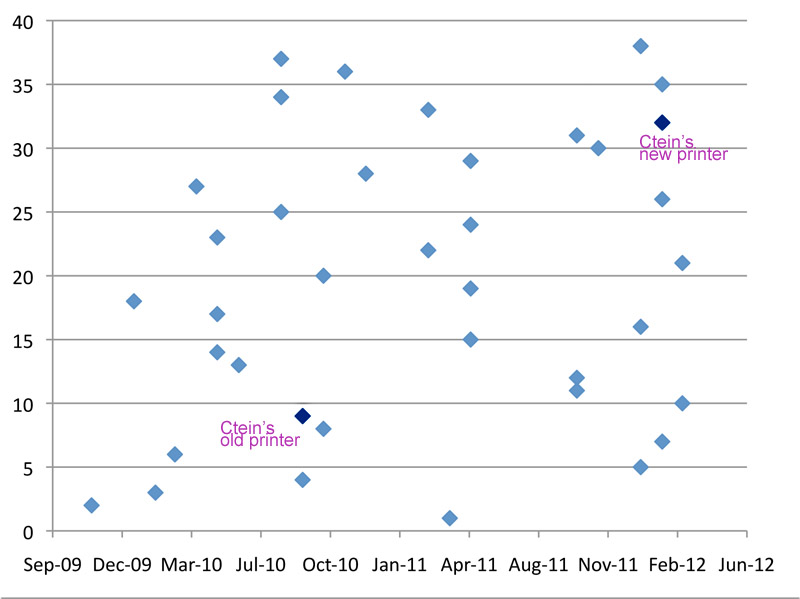

Figures 1 and 2: scatter plots of print quality (by ranking number) vs. date of printer purchase. It's the same data in both figures, the axes are swapped between the two of them because sometimes correlation patterns stand out better one way then the other. In this case, there is no pattern; it's about as random as you can get.

Well, a pattern sure jumped out at me. The print quality was totally uncorrelated with time. This is about as close to a random scatter plot as I'd ever expect to see from real-world data. Epson was right. I was wrong.

Dammit.

In both plots I've labeled my current printer and my original printer. Yup, the original printer was considerably better than average while the current one is worse. Ah well.

Mind you, my new one is still a very good printer. Nobody who's ever gotten prints from it has said a negative word about the print quality (including the 750 of you who recently took advantage of the $19.95 print offer). The printer gets high marks. It's just that my old printer got an A+. He whined.

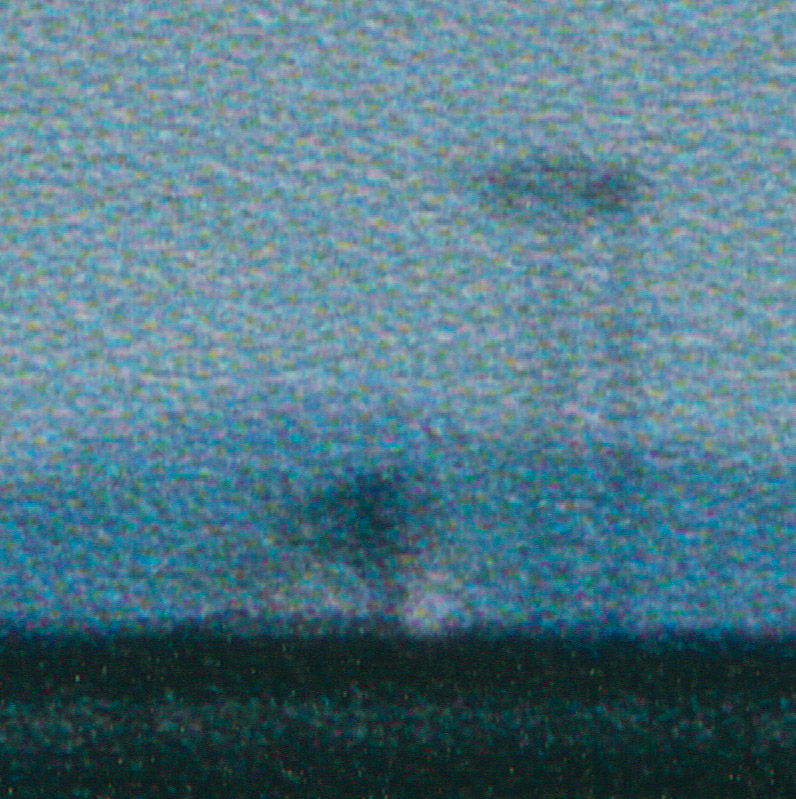

Figures 3 and 4: high-resolution scans of prints from the best and worst printers in the lot. This is about a 40X magnification; you'd have to stand back 60 feet from your display for the ink droplets to appear as they would in a real print viewed closely.

Still, the difference in quality from best to worst is considerable. Figures 3 and 4 show very high-resolution scans of prints from the best- and worst-ranked printers. The difference you're seeing there is greater than the difference between printing at 1440 dpi high-speed and 2880 dpi low-speed. In fact, it's comparable to the difference you'll see between entire generations of printers. In other words, the very best of these 3880 printers is right up there with the 4900 printer quality. The very worst is down at the printer quality of the previous generation of printer.

So, what can you do about this? Nothing. What can I do about this? Nothing. But, ain't it interesting!

Getting back to the point of Part I, it's a good lesson in why you should take reviews that peer too minutely into equipment quality with a certain very small grain of salt.

Or perhaps a rather large chunk of halite.

It's one of those random variation things, you know.

Ctein

Custom Printer Ctein's regular weekly column usually appears on Wednesday but was delayed this week because of Editor Presence Variability (EPV).

Featured Comment by Sareesh S: "This is an excellent article in the best traditions of information-sharing on the web. Thank you for taking the effort and sharing!"

Mike adds: That's what I thought too. Taking Part I and Part II together, this is among Ctein's best articles for TOP. First an informed and judicious discussion of the general principles, then a specific example with original site-sourced research, clearly presented and well illustrated. Kudos to columnist Ctein from the Humbl. Ed.

Featured Comment by Paul Maxim: "I've scanned through all of the other comments and didn't notice anyone bringing this up, but if I missed it, I apologize.

"As a statistician, it occurs to me that something is missing here. While I don't doubt your testing (subjective or not), there's nothing in your published data that shows the 'within printer' level of variability. That is, if you take some of the individual printers and repeat the test multiple times (with independent setups, of course), how much within printer variability do you see? And if you then compare that level of variability with the 'between printer' variability that you've measured, is there a detectable (significant) difference? In other words, is the 'between printer' variability detectably larger than the 'within printer' variability?

"The result of that test will determine what conclusions, if any, that you can draw from the tests.

"I suspect that Epson already knows the answer to that question. And that's why they've said that you're looking at 'normal' printer to printer variability. At least I hope that they know. Otherwise, there truly is a hole in their quality system."

Ctein replies: Ah, good point! For a given printer, printing on a given paper, there's very little variation in quality from print to print or session to session. I can't say for sure there's none, but it's so small that it's smaller than any of the other sources of data "noise" I'm dealing with.

_files/patreon-2.gif)

Love this stuff, keep it up.

Posted by: Peter | Friday, 06 July 2012 at 12:46 PM

"But, ain't it interesting!"

Yes, it is.

"A great deal more is known than has been proved."

-– Richard Feynman

Although the results are not immediately beneficial you should be proud of having proved what is normally a cynical supposition. I suspect that there will be a group of technicians sitting with knit brows in a Japanese conference room poring over your data soon.

Posted by: Kenneth Tanaka | Friday, 06 July 2012 at 12:50 PM

It looks to me like the driver has chosen different amounts of ink to mix. The 'poor' version has definite chunks of cyan mixed in and probably some greys as well whereas the good one has mostly light cyan instead. Yes there is a boat load more dither too but could this be a case of different versions of firmware or driver/os introducing variation too?

Posted by: Tim Parkin | Friday, 06 July 2012 at 12:51 PM

Am I correct to assume that these sample variations are, for all practical purposes, invisible to the naked, unaided eye? In other words, would I have to examine a print with a microscope (40X loupes being rather rare) to see the difference that is so obvious in your hi-res scans? If so, was it simple scientific curiosity that motivated you to take such a close look at the prints from the replacement printer?

I ask because despite the careful qualifiers in your 2nd and 3rd paragraphs, there are some who are all-to-eager to build mountains out of molehills and jump to faulty conclusions. In short, in your opinion there is no cause for concern, right?

Posted by: Gordon Lewis | Friday, 06 July 2012 at 01:01 PM

Given the complexity of printer technology, your findings do not surprise me.

So... Did you make an offer to buy (or swap your current printer for...) one of the "better" printers from the respondent pool?

Posted by: Michael | Friday, 06 July 2012 at 01:02 PM

This really shouldn't happen.

What you have done is tantamount, in my eyes, to a superhuman feat, and a great lesson for the interwebs... if you are going to call someone out, especially a manufacturer, you need a method that satisfies common sense and is backed up with evidence. To my eye there isn't anyone who could have mustered the kind of resources you did in order to make this particular point, and, you have accounted for skeptics such as myself. What if one does all the right things, and it ends up being the expensive widget? What are we willing to tolerate as consumers without being labeled a measurebater?

I tip my hat to you sir, it is interesting.

Posted by: Taran | Friday, 06 July 2012 at 01:04 PM

I hope EPSON learned something from this. They should be able to figure out why it's better, and apply it to future engineering.

Posted by: Bill Mitchell | Friday, 06 July 2012 at 02:08 PM

This story is kind of depressing Ctein! I wonder if there's a market for Epson to sell a ELITE or SPECIAL EDITION version of every product which has been built to tighter tolerances. (I was thinking of high end hi fi gear when I read this story...)

Pak

Posted by: Pak-Ming Wan | Friday, 06 July 2012 at 02:11 PM

In the competitive world of professional printers, your data and samples may lead the company to improve on the consistancy of its printers. Their competitors cannot be lax either and they may well be reading this column too.

Posted by: Mathew Hargreaves | Friday, 06 July 2012 at 02:17 PM

Now I'm just curious to know which of those unidentified data points corresponds to my own sample (as I'm sure all the other contributors are). It's probably best not to know since I'm already very happy with the print quality.

Posted by: Tyler | Friday, 06 July 2012 at 02:40 PM

After all that would it be possible to let us know where our printers rated?

Posted by: John Brewton | Friday, 06 July 2012 at 03:05 PM

Ctein,

A question and a request.

Question: Was you ranking of the prints subjective or did you have an objective measure of noise? If the former then I'm afraid I've got my doubts about your rankings being right at the fine level. It's easy to pick 1 and 40 apart (or even 1 and 10) but 4 and 5 will most likely be subjective.

Request: Please label your axes.

Cheers,

Bruce

Posted by: Bruce Crawford | Friday, 06 July 2012 at 03:28 PM

Dear Ken,

In truth, I envision a group of smug engineers, since I confirmed what they'd been telling me all along, despite my dark suspicions of a QC failure.

~~~~~~

Dear Tim,

That's an optical illusion caused by the different dot pattern. The different printers are laying down the same amount of each ink. Otherwise, I'd be seeing very different color balances in prints made using the same profiles. As I mentioned in the article, my "good" and "bad" printers produced just about identical prints, tone- and color-wise, with the same custom profile.

~~~~~~

Dear Gordon,

No, the difference is not invisible to the naked eye. If I point it out to people, they can see the worst printers produce very slightly "grainy" prints while the best printers produce grainless-looking prints. But it's down at the level where most other folks just don't care.

I have no doubt that there are folks who will quote this article out of context to create great molehill-sired mountains. Won't be the first time. I did my best, just gotta ignore it.

~~~~~~

Dear Michael,

Hmmmm, that never occurred to me.

Now I guess I'll have to think about just how much it's worth to me (money and time/trouble) to get a primo unit.

pax / Ctein

==========================================

-- Ctein's Online Gallery http://ctein.com

-- Digital Restorations http://photo-repair.com

==========================================

Posted by: ctein | Friday, 06 July 2012 at 03:32 PM

I suspect this is the unavoidable result of living at the bleeding edge of technology. This degree of reproducible precision in droplet placement from inkjet printers available today (and this part is key) for a very reasonable price, is right at the limit of what's feasible. Certainly we could have tighter, more reproducible dot placement...if we were willing to pay two or three times as much per printer. It's easy to build a great car for $100,000 per unit; it's damned hard to build a great car for $20,000.

I have a nodding familiarity with aviation technology, and find similarities there. Circa late 1950s/early 1960s, Convair built the incredible and futuristic B-58 Hustler bomber, which could fly faster than almost any fighter jet of its day. It was cutting edge technology. But its nuts 'n bolts operating systems, particularly its hydraulic controls, proved to be insanely maintenance intensive and nearly impossible to keep within operational tolerances. It was retired within a few years of deployment because, as advanced as it was, the thing was just too difficult and complex to fly & keep in the air. Perhaps consistency in dot placement accuracy is right at the limit of what's possible for Epson, hence the unwelcome variation from unit to unit.

Posted by: Geoff Wittig | Friday, 06 July 2012 at 03:36 PM

Based on this data, how many 3880 do I need to buy to be sure to get an A+ one?

Since I can't really do that because, I also have to find out "How many 24-70mmm f2.8 do I need...', and so on, I'll have to consider revising my stance on extended warranties: they sent Ctein 3 printers! Unwarscheinlich!

Hmmm, wonder if this variation explains why my prints of night scenes are, how shall put this, too dark... ;-)

Posted by: Kaemu | Friday, 06 July 2012 at 03:37 PM

"Smug engineers" isn't necessarily right, but if one of them were to look into it further I'm sure their management would talk them out of it.

Posted by: michaelg | Friday, 06 July 2012 at 03:47 PM

@ John Brewton:

Are you certain you really want to know? It's one thing if your printer turns out to be a standout performer, but quite another if it turns out to be a dog.

Posted by: Jeffrey Goggin | Friday, 06 July 2012 at 04:23 PM

Fascinating story. I also went through 3 Epson printers (the R3000 model), though for a different reason. My First R3000, purchased from B&H, wouldn't load paper from the front feeder. Or rather, it would load the paper perfectly and then display an error message saying the paper hadn't loaded correctly. After an hour on the phone with a very knowledgeable and helpful Epson tech support staffer (we went through everything step-by-step several times to make sure the problem wasn't user error) they shipped me a replacement printer overnight, complete with a prepaid shipping label for the old printer. The only problem being that they didn't pack the replacement printer properly and it came out of the box pretty much destroyed. A third printer was dispatched. This one arrived safely but exhibited exactly the same problem as the first one!

My second tech support rep was much less helpful and friendly than the first and tried to blame everything on my use of non Epson-brand paper (so there's variability amongst personnel as well as product). I eventually had to buy some Epson paper just to convince him.

As it stands now, I still have the third printer, not wanting to risk another multi-step replacement scenario. I'm now thinking of taking it to a good Epson authorized service center (there's one not far from me who did a brilliant job on my old 2200) to see if I can get the issue fixed rather than gamble on a replacement unit.

At least it prints nicely!

Posted by: Mark Roberts | Friday, 06 July 2012 at 04:27 PM

Dear John,

Other than possible bragging (or crying) rights, what would you get from knowing? I think Tyler's got the right attitude.

~~~~~~~~

Dear Bruce,

Yes, visual comparison, so position is only precise to a couple of places either way. But then, so is the date.

If there'd been anything remotely resembling a pattern, I'd have refined the analysis. With this scattershot a result, the noise introduced by the methodology is unimportant.

~~~~~~

Dear Kaemu,

Well, with the A+ units being in the top 15-20%, you'd have to buy 10-15 printers to be 90% confident you'd gotten one.

A lot less work and money just to buy a 4900.

pax / Ctein

Posted by: ctein | Friday, 06 July 2012 at 04:58 PM

Gee, now I'm wondering whether my printer (Aug 2010) is the "good one" or one of the bad ones on your plot. I have never had reason to question the output quality before as I have always considered the prints from my 3880 to be excellent - certainly no complaints from any clients. Still, you have now given me one more thing to obsess over. Thanks.

Posted by: Mike Rainwater | Friday, 06 July 2012 at 04:58 PM

There was a story circulating a few decades ago concerning the testing of a certain E. Leitz lens--I've forgotten which lens, sorry. If I'm remembering correctly, the purpose of the test was to determine consistency. One of the senior optical scientists from E. Leitz Wetzlar was asked to perform tests of several samples of this particular lens design and report his findings.

The Leitz man was reluctant, saying, "But these are all E. Leitz lenses...they are all superb."

But he was persuaded to complete the test procedures. Afterwards, he was asked to report on his findings. He held up one of the tested lenses and stated, "They are all E. Leitz lenses. They are all superb. But THIS E. Leitz lens is a little more superb than the others."

Even in excellence, some things are more excellent.

Posted by: Dogman | Friday, 06 July 2012 at 05:18 PM

Smug engineers at Epson? Not in my experience, at least the ones I worked with from Japan. I was at an Epson developer conference under NDA when Ultrachrome was launched. The engineers showed us electron microscope images of ink droplet formation, from other ink technologies, and what they had done with Ultrachrome at 30,000X enlargement! I remember thinking. "wow are these guys ever into ink!" So they really do pay attention!

Before that I realted to an engineer how my customers in the printing industry thought the way a 9000 series printer "swayed" while printing reflected poorly on its design. Even though we both knew it was designed that way to compensate for the moving mass of the head, he hung his head in shame. The next series 10000 printers didn't so much vibrate when printing.

So I think that even though they expected the results Ctein got, they will think of them in their next designs!

Sean

Posted by: Sean Murphy | Friday, 06 July 2012 at 05:41 PM

Great article as always Ctein.

I am on my fourth Epson 3880. The first died on the 3rd day; the replacement was obviously refurbished, though Epson tried to assure me it was not. It was unable to print black-and-white pictures with large expanses of pure black on matte paper instead giving white jagged lines in the middle of the picture.But ok on Glossy or Lustre papers. All my papers are made by Epson.

The Third was similar.

The fourth, my present one, is ok. Simple test for me is to print a 16 x 20 print of pure black, on Epson Enhanced Matte paper. If the printer can't do that, it's a failure.

Posted by: ben ng | Friday, 06 July 2012 at 06:03 PM

I am amazed that you had any luck with Epson. I own a 7800 and had a very insoluble clog and got NO help from the company other than a repair contact person for in studio repairs at a price that at minimum would have cost me five hundred dollars plus..I could not obtain from them a repair procedure nor suggestions how to repair this myself nor the shop manual nor parts that I might need nor well..anything. They stink when out of warrantee and not a web presence person they fear will write negative about their service which I suggest is why rhey helped you and did not give me the time of day.. They fear you but I, they basically left me on my own to muddle through. In the end I found a manual called a field guide on line for a company that uses the Epson modified somehow for their own uses and figured out from that how to dissemble the ink lines, suck out the clog from the valve at the cart end...not the head which is what they implied I would need to have replaced...and with a load of Windex in a set of carts, I cleaned the entire system and am back into printing ..no thanks to Epson. The printer always makes great prints so long as one uses it a lot..clogs otherwise. Epson process for cleaning is a farce of wasted ink. It has no real system that works consistently and my difficult process did the job but after warrantee good luck to you all. There is plenty of half truths out there in this or that cleaner but I do not recommend any method but what I did worked for me twice. I have been told that the newer heads clog less but are much more delicate so one cannot clean them with the wetted paper towel routine one reads about online. I can only wish you all good luck with Epson but will I buy another machine from them? Resounding answer is never ever..

Posted by: Neil Fiertel | Friday, 06 July 2012 at 07:34 PM

It looks like Monet versus Seurat.

Posted by: John Willard | Friday, 06 July 2012 at 08:14 PM

Hi Ctein,

Please look for the Epson adjustment utility online. It's a bit of software Epson techs use to calibrate printers after installing a new printhead or making other major hardware fixes. With my Epson R1800 I used it to solve a banding issue I had. There are quite a lot of parameters to adjust and you may be able to improve your printer's output through experimentation.

Roger

Posted by: Roger | Friday, 06 July 2012 at 08:29 PM

I'm assuming all these tests used uniform paper, driver versions, driver settings, color profiles, and OS's? Since the data was crowdsourced, I have to wonder how much induced variability might be masking a pattern with randomness.

I would think even something like altitude changes, humidity, or ink levels could impact droplet shapes/patterns.

I would think you'd need to be under more controlled conditions to get viable results than is practical. That's a shame.

Posted by: Mike Sims | Friday, 06 July 2012 at 09:11 PM

"I hope EPSON learned something from this. They should be able to figure out why it's better, and apply it to future engineering."

I'm willing to bet quite a lot that EPSON would see this simply as confirmation of what they already knew. (Which is the reason for the smug engineer references above. :)

It's not like their engineers wouldn't be analyzing everything in the printer for variability and looking at how to get rid of it when designing and refining it. The problem is one of cost - to get rid of the variability, the cost is would be significant. So as someone already suggested, they could probably make a tighter controlled 3880, but it would probably cost several times as much as the current one.

Engineering is not about creating perfection; It's about balancing all the trade-offs and optimizing the most you can within the limits of the product goals and costs.

Posted by: David Bostedo | Friday, 06 July 2012 at 09:13 PM

I use a wide-format Canon printer and it has head alignment routines in its firmware. Do your Epsons have this, and did you run them?

Posted by: Kirk Thompson | Friday, 06 July 2012 at 09:39 PM

"A lot less work and money just to buy a 4900."

Ah, but would the 4900 not be subject to the similar levels of sample variation?

I kind of like the idea of having a selected "+" or "Gold" or "Pro" version. CPU and memory makers do this already in practice; the chips are basically identical, but defects and sample variation determines what clock speed they support and what features are enabled, with different prices as a result.

So they could sell a curated "Pro" version at, say, 40% premium, with a cherry-picked unit and a special pro-level guarantee and service, perhaps with a hotline directly to the escalated tech level not available to the unwashed masses.

Posted by: Janne | Friday, 06 July 2012 at 10:28 PM

I appreciate graininess in a print. It sounds as if I might appreciate your replacement printers more than the original version that you hold in such high regard.

Posted by: Player | Friday, 06 July 2012 at 11:35 PM

Very interesting. What about other variables, such as the paper and the ink? Like the printer itself, paper and ink can vary from batch to batch. I'm sure you specified the paper, but your original request doesn't say you would provide it. Other possibilities might include the moisture content of the paper and static electricity on a dry day.

Perhaps none of these makes much difference, but it would nice if you commented on them.

Posted by: Randy Cole | Friday, 06 July 2012 at 11:35 PM

Dear Ctein,

40x? That would be viewing a slide at 10x with a 4x ocular lens.

I love that there exist engineers that will dither about the tree at 1000ft showing seven branches or eight when the eyelash (point of focus) has printed the mitochondria within the eyelash; also, I am positive that it is people like you drive Epson to ensure that I receive a printer that makes me money right out of the box.

Don't stop caring about that 40x and please write a bazillion articles about the randomness of exactness.

I had no idea that you were a driving force behind my 3880 being great.

Thank You,

My 4 lenses (from my 3880 profits) thank you too.

Write more physics article too please.

Posted by: Kosch | Saturday, 07 July 2012 at 12:19 AM

"I kind of like the idea of having a selected "+" or "Gold" or "Pro" version. CPU and memory makers do this already in practice"

@Janne - This practice goes way back.. the earliest example I can think of is engines for the Atlas missile... For a while, they'd test the engines and the best (highest thrust) would be used for boosters destined for Project Mercury.

Posted by: Derek Lyons | Saturday, 07 July 2012 at 12:22 AM

Circa 1965 Japanese manufacturers showed us that mass-produced cheap consumer electro-mechanical goods could be produced to the highest (and then very expensive) quality control standards achieved by Western manufacturers.

Before that, we took it for granted that random sample variation was a fact of life for us plebian consumers. Much effort was expended by my parents' generation in "getting a good piece" when shopping for a camera and such. Not because they were obsessional, but because there was a real chance of getting a lemon if you did not pay attention.

A generation later, we are totally spoilt, expecting quality control and tolerances in manufactured goods that are so tight that it takes careful testing to spot it.

We obsess over minutiae that don't make the slightest difference to our everyday purposes in using these machines. We are perfectly happy to send a friend a cell-phone camera picture one minute, and then agonize over whether we should get a 24 or 36 megapixel camera the next.

We are neurotic now, not merely careful, unlike our parents.

Posted by: Mani Sitaraman | Saturday, 07 July 2012 at 12:24 AM

Dear Michaelg,

Why would you think that? There's no percentage in it for Epson having a defect in their product or quality control.

My contact within Epson is high enough in the food chain that had I been able to demonstrate there was a problem, he'd be in a position to effect changes.

~~~~~~

Dear Mike Sims,

I know how to control for all of that stuff in this particular case. But in general, you are right. It is not possible to crowdsource most research. There are too many ways your minions can screw screw up the experiment. It's so difficult to get good minions these days…

Truth is, I happily surprised myself when I realized that I COULD work out a robust experimental protocol for studying this. With most product variability problems, I wouldn't be able to.

~~~~~~

Dear Kirk,

Yes, that was one of the “is it plugged in”'s that we checked. Ran both automatic and manual head-align routines. Didn't make any difference. My printers were in very good internal adjustment. Dammit, again, he said.

~~~~~~

Dear Janne,

No doubt, but the 4900 starts at so much higher a level of quality (with regards to this particular characteristic) that even a lousy 4900 would be substantially better than most (maybe all) 3880's.

The real and practical problem for me is that I simply can't fit a 4900 in my office. It's huge compared to a 3880. It would require a substantial reorganization of my office and moving a lot of stuff out of it which, currently, has no place else to go.

A related problem (for me) is that it's my understanding that there will be no “3900;” the print engine in the x900 series is so much larger than the x8x0 series that it just won't go in the smaller chassis.

That's not to say that Epson won't come out with some new printer that's better than the 3880; no doubt something is in the works (they haven't confided in me). But they dashed cold water on my hopeful inquiries that a 3900 might follow on the heels of the 4900.

pax \ Ctein

[ Please excuse any word-salad. MacSpeech in training! ]

======================================

-- Ctein's Online Gallery http://ctein.com

-- Digital Restorations http://photo-repair.com

======================================

Posted by: ctein | Saturday, 07 July 2012 at 01:13 AM

If TVs and monitors, and just about all visual equipment can be fine tuned calibrated for opitimum display, then a sideline business might be specialized in doing the same for printers. You can buy an off the shelf TV calibrated by the manufacturer for good dislay during all light levels around it. You pay extra to have the TV calibrated to its true and accurate display level. For an extra $200 at the time of purchase, you have the printer fine tuned for optimum output.

Posted by: Mathew Hargreaves | Saturday, 07 July 2012 at 03:23 AM

My thought is that generating the ink drop is almost certainly an "open loop" operation. You put in a pulse of electricity, and some amount of ink pops out. Each ink head probably has slightly different sizes of holes, slightly different activities of the peizoelectric element, etc. There's no way the system can measure how many picoliters of ink come out for a given electrical pulse, so the system is "open loop," there's no negative feedback to correct for errors.

There may be some calibration process at the factory, or they may just accept the variance in the heads. Of course, a "wet" print head would print darker, but you would calibrate that out when you profile the printer.

Of course, this does loudly raise the question of why does Epson insist on the print head not being user-replaceable? Canon is able to do that with no problem, and no bad effects. To me this is one of the most arrogant aspects of how Epson runs their printer business.

Of course, maybe the reason that the print heads are not user-replaceable is that Epson can't make them highly repeatably, and there's a lot of open loop calibration in the factory. But even that could be addressed by calibrating them in the factory, and storing the calibration data in an EEPROM in the print head.

Posted by: John Shriver | Saturday, 07 July 2012 at 05:59 AM

...so again, why is all this easier than when I used to print analog color?

Posted by: Crabby Umbo | Saturday, 07 July 2012 at 07:23 AM

I'll stick with Canon, thank you. Never had a clog, or any other such problem. Plug and play, period.

Posted by: paul richardson | Saturday, 07 July 2012 at 08:54 AM

Very interesting. I have to ask...did the test use bidirectional or unidirectional printing?

I do a fair bit of work with digital negatives, and the differences between printers and printer setup can be far more visible than on a regular print. I can do bidirectional calibration using an optical microscope, and it just doesn't matter; a platinum print done with a bidirectional inkjet negative has clearly visible gritty midtones when compared to a print from a unidirectional negative.

Even if your test was done unidirectionally, I wouldn't be surprised if anyone who wants a quality boost would get more mileage out of going unidirectional than from swapping printers.

Posted by: Clyde Rogers | Saturday, 07 July 2012 at 10:00 AM

Clyde,

What do "bidirectional printing" and "unidirectional printing" mean? I've never heard those terms before.

Mike

Posted by: Mike Johnston | Saturday, 07 July 2012 at 10:09 AM

Thanks Ctein! (and Mike) (and the TOP print participation).

Posted by: darr | Saturday, 07 July 2012 at 10:50 AM

I believe that "bidirectional" refers to the high speed setting in the print settings tab of the Epson driver. At least that's where it is for my 2880.

Posted by: Robert | Saturday, 07 July 2012 at 11:08 AM

Ctein--

Looking at your plots, what's interesting to me about all this random variation stuff is that you are, perhaps, lucky in that you didn't get a "cherry" of data. In some parallel universe somewhere, you did not get responses from many of the 8 or so folk most off the diagonal in the upper-left part of the plot, and you didn't also from the four people in the lower right. That Ctein will have written a just-as-awesome article that damns Epson's manufacturing: "A-ha! Just as I suspected..."

But you must be right that Epson's right. Does not look like there's a date of manufacture trend. This Ctein universe, and presumably an overwhelming majority of others, gets to relax, say "come what may", but still marvel.

(hmm... probably all these higgs boson articles I'm reading may be infecting this post)

Posted by: xfmj | Saturday, 07 July 2012 at 12:41 PM

Dear Mike,

In Epson terminology, “high-speed” and “low-speed” are the same as "bidirectional printing" and "unidirectional printing" (other printer manufacturers may use different terminology).

In bidirectional mode, the printhead deposits ink each time it passes over a spot in the paper as the printhead moves to and fro, left to right and back again. In unidirectional mode, it only deposits ink when the head moves “fro.” Unidirectional printing takes twice as long, as a result, but it produces finer “grain” because the print head can deposit the ink droplets more accurately. Printing in both directions creates backlash-sorts of problems that the printer has to deal with.

With today's higher-end printers, there often only a modest difference in quality between the two printing modes, especially if one takes care to periodically run head alignments. In fact, with something like the 3880, there is surprisingly little difference in graininess between 1440 dpi bidirectional and 2880 dpi unidirectional. It's there, but probably the majority of 3880 users are running at the lower setting and entirely happy with it. Nonetheless, Clyde is entirely correct; if you're kind of anal about this (guess who?) and printing time isn't an issue, you're always better off just leaving the quality setting at 2880 dpi low-speed/unidirectional.

~~~~

Dear Clyde,

As I mentioned in the article, the spread in quality between best and worst is considerably greater than that caused by changing the printing settings. That is, at 2880 dpi low speed, my new printer produces distinctly grainier prints than my old one did at 1440 dpi high speed. If someone is currently running at the lowest quality setting, it would behoove them to switch to the highest before switching printers (it's certainly a heck of a lot cheaper) And see if that makes them happy. Overall though, the spread in printer quality is much larger than that produced by changing settings.

pax \ Ctein

[ Please excuse any word-salad. MacSpeech in training! ]

======================================

-- Ctein's Online Gallery http://ctein.com

-- Digital Restorations http://photo-repair.com

======================================

Posted by: ctein | Saturday, 07 July 2012 at 01:48 PM

Dear Neil,

I'm sorry to hear you had so many problems with your printer. But the reason I got treated so much better has nothing to do with my web presence, it's because my printer was under warranty. Printer repairs are expensive! When I ruined my Epson 2200 printer with an unclearable head clog by not using it for nine months, the cost of repairing it was so high that I just trashed it.

As it happens, my original 3880 was still under factory warranty (barely) but I had still planned to buy the extended warranty. It's like buying fire insurance. Averaged over large numbers of policies, you won't make money on fire insurance (or an extended warranty). The insurer does! What it does is protects you against catastrophic loss.

As for being able to escalate this beyond normal technical support (which I would remind you included three printer exchanges), that's not because I'm a squeaky wheel on the Internet; they didn't even know who I was. 'Sides, there are lots of ignorant squeaky wheels on the Internet, and companies have learned to correctly ignore them. If I got the number of page hits that Michael Reichmann or Ken Rockwell does, that would be a different matter. I'm a small player. The reason I get paid attention to is that I am respected. To those in the industry who know me, they know I know how to do my research and don't go off half cocked. The ones who know me really well know that this wouldn't be the first time I had uniquely uncovered a major product problem; I've done it at least four times in my career, and every time the company has been exceedingly grateful for my discoveries.

I can understand why you never wanna own an Epson printer again, but I would recommend that no matter what printer you own, you buy the extended warranty if it's available. I'll say it again, printer repairs are EXPENSIVE!

pax \ Ctein

[ Please excuse any word-salad. MacSpeech in training! ]

======================================

-- Ctein's Online Gallery http://ctein.com

-- Digital Restorations http://photo-repair.com

======================================

Posted by: ctein | Saturday, 07 July 2012 at 02:16 PM

Dear Randy,

Good question! And it relates to Mike S's earlier question about external variables, so if I may be allowed a somewhat digressive answer…

The big trick to being a good experimentalist is not figuring out how to make an accurate and precise measurement. That's the easy part of designing an experiment. The hard part of designing an experiment is being able to figure out all the important external variables and factors that might screw up that answer and being able to either take them into account or null them out.

That's a major part of why you usually can't have minions do your work for you. Along with many of them not being competent to make precise and accurate measurements, you can't easily control or specify the conditions they make those measurements under. Most of the time, crowd sourcing research simply won't work. For example, Lloyd Chambers has written at some length about the focus accuracy problems of digital cameras. That's something that would be fun to research, but I can't figure out how to crowd source the experiments-- there are too many ways for the minion to screw it up and too many uncontrollable factors (absolute light level, subject contrast, arrangement of fine detail, etc.) that can produce different results. This printer business was a very unusual situation.

Another detail worth mentioning: remember that I've been using this model printer for over a year and a half and run thousands of prints through several different units of it. I not only have a good feeling for what external variables affect print quality, I can run specific tests all by myself, seeing the effect of different papers, different software operating systems, etc. I actually could nail most of the Jell-O to the wall, leaving only a few runny bits.

I can tell you that there is essentially no effect from ink variability; I have run a lot of ink cartridges through these printers! Ditto paper variability. But the kind of paper does make a difference. The results are slightly different depending on which glossy/semiglossy/Luster paper you use, although not by very much. (Matte or textured papers were right out, of course.) It was something I had to control for and I required people to print on one of two papers I specified unless they asked specific permission to do otherwise, and then I only allowed if it was a paper that I also could produce reference prints on at my end.

In any case, all of these things do add a bit of noise to the results. But then, as I mentioned earlier, so does the actual date of manufacture vs. the date of sale and my eyeball evaluation of graininess vs. running them through something like a scanning densitometer (which I would have preferred, but I don't own one).

Had I seen the faintest hint of a pattern, I would have gone back and re-analyzed the experimental results to reduce those sources of noise. When there is such a blatant absence of pattern as in this case, there's no need to.

pax \ Ctein

[ Please excuse any word-salad. MacSpeech in training! ]

======================================

-- Ctein's Online Gallery http://ctein.com

-- Digital Restorations http://photo-repair.com

======================================

Posted by: ctein | Saturday, 07 July 2012 at 02:34 PM

Dear xfmj,

Yeah, if I cherry pick which third of the data to throw away, I can create a clear trend line [VBG]. That's one of the reasons for wanting something like 40 data samples, it makes the odds of that happening by accident very small.

That was the main reason for wanting so many respondents. Small data sets easily produce anomalous results. In fact, when I first started on this, I asked three or four friends, who are careful workers, to provide me with print samples. Combined with the few samples I had from my own printers, I saw evidence that something had gone wrong in Epson's quality control; there were very distinct groups of data between the time period for my first printer and my last printer.

Only problem, six or seven data points don't mean a lot. Especially since, if I threw out any one of those data points, it markedly changed my impression of whether or not a pattern existed. That's clear evidence that nothing has been proven; real results are never sensitive to one or two data points. But it is why I went into this strongly suspecting that I would find a quality control failure (beyond wishful thinking, that is).

From a practical point of view, it wouldn't have done me any good. At least, not immediately. If I did prove that Epson was making worse printers today than a year ago, that wouldn't get me a better printer. Sometime down the timeline, sure. But not now.

pax \ Ctein

[ Please excuse any word-salad. MacSpeech in training! ]

======================================

-- Ctein's Online Gallery http://ctein.com

-- Digital Restorations http://photo-repair.com

======================================

Posted by: ctein | Saturday, 07 July 2012 at 02:49 PM

@Mani Sitaraman - Case in point, I dabble in competitive shooting. A rifle's inherent accuracy - the accuracy that the mechnism is capable of minus external variables - is minutes of angle (MOA). A minute of angle works out to about an inch at 100 yards, so a MOA capable rifle will put all it's bullets within a 1" circle at 100 yards, assuming the rifle isn't moved and there's no wind and the person pulling the trigger doesn't alter the parameters between shoots.

An MOA rifle used to be fairly extraordinary, a kind of shooter's Holy Grail. And a great deal of time and effort was put into crafting rifles of that level of precision, finding and pulling from production the samples that varied into that level, or customizing rifles to reach and exceed that level. But now, thanks to modern manufacture, MOA capable rifles are rather trivial to make. Several company's budget hunting rifles routinely are sub-MOA, right out of the box. And so, when some guy buys a $300 deer harvester and it shoots 2-3 MOA (which was perfectly acceptable accuracy for the vast majority of people, who have neither the need or the skill to exploit a high precision rifle, from the dawn of firearms until 10-15 years ago)it is now an inaccurate piece of junk.

I suspect that a) we are extremely spoiled by modern manufacturing tolerances and QA processes, and b) unless you're printing at the level of Ctein, one could print their entire life with one of the 'poor' printers and be perfectly happy.

Posted by: Ray | Saturday, 07 July 2012 at 03:12 PM

@ Mike J.:

"Bi-directional" printing means the printhead is printing in both directions as it passes over the paper and "uni-directional" means that it's printing in only one direction.

I can't speak to how bi-directional printing is accessed with other printers, but with Epson printers, one gets bi-directional printing when one selects the "high-speed" option in the printer setup menu.

Many people see no difference in print quality between the two settings and therefore choose "high-speed" because it cuts the print time roughly in half; many others, such as myself, do see a difference in print quality that favors uni-directional printing and thus we live with the slower print times.

Posted by: Jeffrey Goggin | Saturday, 07 July 2012 at 05:39 PM

Robert is correct, using the Epson driver, selecting "High Speed" makes the printer spray ink while the head moves across the paper in both directions. If you uncheck "High Speed" (or select unidirectional printing directly in drivers like QTR), it sprays ink only when moving in one direction.

The Epson printers I've used have a utility to calibrate the printer to improve bidirectional printing, but in my experience, it never matches up to unidirectional printing (at least when making digital negatives).

Posted by: Clyde Rogers | Saturday, 07 July 2012 at 08:39 PM

Oh, and of course, it takes about twice as long for a print to complete in unidirectional mode...

Posted by: Clyde Rogers | Saturday, 07 July 2012 at 08:40 PM

Dear Ctein,

It's a little disturbing to hear that the difference between printers is greater than the difference between unidirectional and bidirectional (that's a pretty obvious difference in my application). I hope my 3800 keeps working for a long time, it sounds like it may be hard to find another good digital negative printer.

Later,

Clyde

Posted by: Clyde Rogers | Saturday, 07 July 2012 at 09:19 PM

Could it also be the ink? Old vs. new? A revised formula? The smoother example looks like the ink may have had a lower viscosity. The grainy example shows large clumps like splatters of ink. The physical differences would very slight and possibly barely measurable, but enough to cause the effects we see.

Posted by: David L. | Sunday, 08 July 2012 at 02:09 PM

Dear David L,

No, it's got nothing to do with the ink.

pax / Ctein

Posted by: ctein | Sunday, 08 July 2012 at 04:36 PM

Remember that your first printer had to go back because of a head clog. This is a common Epson problem. The heads on Epson printers are not user replaceable. This is why I will never buy another Epson printer. My previous one got clogged out of warranty and I am not going to pay nearly the cost of a new printer to have the head replaced. If Epson really wants to improve quality for its customers, they should make the heads user replaceable and provide the heads at reasonable replacement cost, like other printers. I do not like products with designed in failure just after the warranty expires. This is bad product engineering and probably a management driven decision. I am an engineer, so I know they would not have done this on purpose without being told to do it for cost cutting and profit reasons. This is a much bigger issue than the slight variation in print grain.

Posted by: NPrincen | Sunday, 08 July 2012 at 05:53 PM

Thanks for your article, was vey interesting. As for myself I have stopped using epson printers years ago because they had too much issues (was maybe out of luck lol).

I recently bought again an espon printer and it has the exact problems you described. I will bin it and take HP instead.

Posted by: Pat | Tuesday, 10 July 2012 at 03:50 AM

Dear Clyde,

Ahhh, but you (and other readers) are assuming that because you like the results you're seeing you've got some kind of "cherry" unit now and so you'll be likely worse off when you replace it.

That's an improbable assumption. Far more likely you've got a near-average unit.

(You might even have a sub-par unit. How would you know without running the kind of extensive comparisons I just did?)

And, when you do have to replace it, you're going to be jumping up at least one generation, maybe two, which makes the odds very low you'll find yourself feeling you're worse off.

pax / Ctein

Posted by: ctein | Tuesday, 10 July 2012 at 03:10 PM

Dear NPrincen, Pat and others,

The notion that the bean counters in any printer company would cut corners in a way that would make the machines significantly less reliable or otherwise more annoying to the customer simply does not make any sense, unless it produced HUGE cost savings. Printers are not where the companies make their money; they make it on the consumables. Because you've decided you will never buy an Epson printer again, Epson has lost far, far more money on ink and paper from you than they ever would've made from you buying another printer. This market stragety is true of all the printer manufacturers.

That's not to say that printers can't be improved, lord knows they can. But selling printers or their repair services are not the profit centers for these companies. It's the ink and paper that you buy to go with them.

In that same vein, while is immensely irritating to have an unreliable printer (believe me, I have been there!) if you're trying to watch your expenses what you should be watching is the cost of those consumables. For example, even if I had had to totally scrap my 3880 printer last fall and buy an entire new one, I had already run enough ink and paper through that printer that the entire cost of a new printer would've only raised my average print costs by about 20%. Now, I'd really rather not spend that 20%, don't get me wrong. My point is that if I'm looking to keep my printing costs down, what I need to be looking at is how much the manufacturer is charging me for the consumables.

Different companies, even different printers from the same companies, have extremely different operating costs. Ink costs can vary by more than a factor of two, per print, within a company's product line. Between companies, I've seen differences of more than a factor of four. When you consider that the average ink cost for running out a medium-size print is a dollar or so, this quickly becomes a much bigger economic factor for the end-user than printer cost or reliability.

Oh, and by the way, all the printer manufacturers have their dirty little family secrets, when it comes to failure modes. It's entirely understandable that you would not want to be burnt by the same company twice, but don't fool yourself into thinking you've moved from sinner to saint.

pax \ Ctein

[ Please excuse any word-salad. MacSpeech in training! ]

======================================

-- Ctein's Online Gallery http://ctein.com

-- Digital Restorations http://photo-repair.com

======================================

Posted by: ctein | Tuesday, 10 July 2012 at 07:26 PM